data-animation-override>

“Published in NZV8 Issue No. 214”

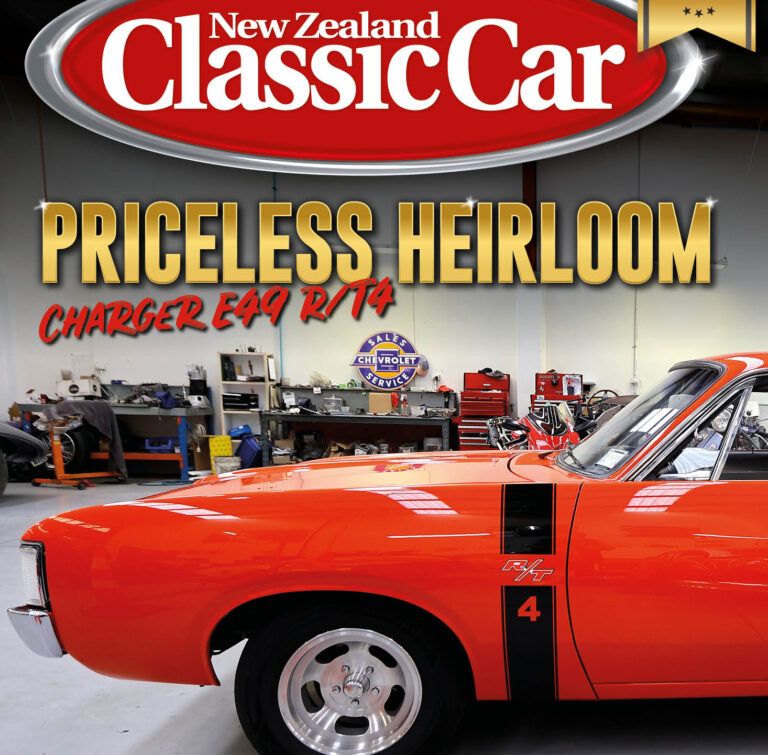

Big power, immaculate presentation and the perfect stance, what more could you ask for in a muscle car.

Knock, knock, knock. Many of us have heard it at some stage. It’s a noise no one wants to hear coming from under the bonnet. The one that sounds like there’s a little man with a hammer going to town on the inside of your engine. If it hasn’t happened to you, cross your fingers, bless your good fortune, and pray to the automotive gods that it never does.

Kyle Kitson, owner of this 1970 Dodge Challenger, clearly hadn’t been praying devoutly enough.

As a member of active West Auckland’s Huapai Hot Rod Club, Kyle regularly takes part in the club’s annual drag day held each November. The 2009 edition will be an event Kyle won’t forget in a hurry. Nor for that matter will his older brother Mike (whose Ford Galaxie was on the cover of NZV8 issue 40).

After helping Mike load the Galaxie onto a trailer after it had snapped its crank and destroyed the block, Kyle set off on the journey home, happy in the knowledge his car had survived the day’s racing. In the lane next to him was good friend and bad influence Mike Bari. Boys being boys, they were winding each other up, making a bit of noise and taunting each other on the journey. All was well until Kyle decided to stop for gas. Once filled up and ready to go, the car was fired into life, only for that little man with a hammer to make an unwelcome visit. After a distress call, Mike reappeared on the scene to diagnose the sound as a spun bearing.

Luckily, Mike also happens to be Kyle’s mechanic.

If you can

Kyle spotted an opportunity. “As you do when rebuilding a motor, I thought I’d take the chance to get a bit more power than it had before,” he says. How much was he after? “We thought about 500hp would be nice. Not over the top, but still enough to have a bit of fun.” Absolutely.

Kyle knew that for whatever reason, Mopar parts tend to be more expensive than those for other makes. So while power was the goal, the intention was not to get too carried away spending a whole bunch of cash to achieve it. With this knowledge Mike took special care to ensure that the build was done right to achieve maximum performance for minimum outlay.

The early-’70s 440 Mopar block was stripped of its old parts and stuffed bearings, and in went some prepped six-pack rods and SRP pistons with file-fit SRP rings. While he was at it, a Lunati Voodoo camshaft was added to the mix and a large-volume sump fitted to the underside. While these items would never help make power, they’d ensure the same thing didn’t happen to this build as had happened to the previous one.

A trip to STA saw the majority of the go-fast parts purchased, including Edelbrock RPM alloy heads, which, although good from the factory, were dropped to Terry Lockley for a bit of custom porting. The heads are fitted with stainless valves and shaft-mounted roller rockers, and have been match-ported to an Edelbrock single-plane manifold and Hooker Super Competition headers.

Also in the parts haul was a bunch of MSD ignition components such as a billet distributor, 6AL ignition, Blaster coil and leads. “We knew a good spark was essential for what we were trying to achieve, so we replaced the lot so as to not have one component let it down,” Kyle explains.

Keep on going

While Mike was assembling the engine at his business, AutoCare Services, the 727 Torquelite transmission was sent to Otahuhu Automatic Transmission Specialists where it, too, was overhauled. During the rebuild it was fitted with a 3200rpm stall converter and a full shift kit.

At the same time this was going on (it’s not true about men not being able to multi-task) Kyle took the engineless car back to his family business, Greenpark Panel and Paint. Although he’d repainted the engine bay early on, he decided to pass the time that he was engineless by panelling and painting the whole thing, engine bay included. The colour of choice was Dodge Viper white from the PPG range. As he’s in charge of the painting side of the business, the spray work is all Kyle’s own, and as you’d expect in a painter’s own car, it’s flawless.

Back at AutoCare Services, Mike had worked his magic to ensure the new motor lasted longer than its predecessor, despite the occasional play down the drag strip and the huge number of street km’s it would soon receive. With the big block mated to the transmission and dropped back in the hole, the car was fitted with a B&M shifter and sent off to C&M Performance for some dyno tuning.

With Carl Jensen doing what he does best to the Quick Fuel 850cfm carburettor, the car spun the dyno to an impressive 370hp at 5700rpm. Factoring in drivetrain losses and the like, that’s a solid 560hp at the motor, well up on Kyle’s goal, and all without spending a fortune.

Kyle couldn’t be happier with the outcome and can’t thank Mike enough for all his hard work. “I thought he was crazy when he sent back a piston because it was 10-thou out, but now it’s all been worth it.”

A hard day’s work

Like the engine setup, the rest of the car is also simple, yet super effective. The bright white paintwork and arrow-straight panels are set off well by the big and little Cragar rims fitted with BF Goodrich tyres, while the stance is purposeful yet not over the top on custom springs and aftermarket shocks.

With the interior in great condition when he bought the car, Kyle saw no need to go changing it, and with two- and four-year-old kids often filling the rear seat, that seems like a wise choice. The audio, on the other hand, needed a bit of a shake-up. It now consists of a JVC head unit with Philips speakers front and rear.

The car has only been back on the road for a few months since its unplanned rebuild, but Kyle couldn’t be happier with his Challenger. Some clever thinking and attention to detail in the engine build has seen impressive results. Combine that with an exterior that a painter is proud to call his own, and you’ve got one very tough muscle car for a fraction of the price you’d expect.

Now that’s what we call a cool family cruiser/ weekend racer.

Specs

Engine: 440ci (7.2-litre) big block, early-’70s 440 two-bolt, factory six-pack rods, ARP rod bolts, flat top forged SRP pistons, file-fit rings, balanced, 030 oversize, factory steel crank, Lunati hydraulic Voodoo cam, standard oil pump, large-volume sump, steel balancer, Edelbrock RPM alloy heads, stainless valves, shaft-mount roller rockers, Quick Fuel 850cfm double pumper carb, polished Edelbrock single plane intake, Edelbrock high volume mechanical fuel pump, MSD billet distributor, MSD 6AL ignition, MSD blaster coil and leads, twin 2.5-inch Flow Master exhaust, Hooker Super Competition 1-7/8-inch headers, electric fan and manual fan

Driveline: Torqueflight 727 transmission, 3200rpm 10-inch high stall, full shift kit, Ford nine-inch diff, 3.5:1 ratio, LSD

Suspension: Custom springs, aftermarket shocks

Brakes: Stock disc/drum

Wheels/tyres: 15×6-and 15×10-inch Cragar rims, 225/60R15 and 295/50R15 BF Goodrich tyres

Exterior: PPG Viper White painted by Greenpark Panel and Paint

Interior: Stock with B&M shifter, Auto Meter gauges, JVC head unit, Philips 6x9s, 5-inch components

Performance: 560hp (418kW) at the motor, 370hp (276kW) at the wheels at 5700rpm

Owner profile

Kyle Kitson

Car club: Huapai Hot Rod Club

Age: 37

Occupation: Owner/operator Greenpark Panel and Paint

Previously owned cars: 1969 Chev C10 pick-up, 1971 Pontiac Firebird Formula 455HO, 1968 Pontiac Le Mans

Dream car: Still looking, am happy with what I have right now

Why the Challenger: I just really like the muscle cars, I haven’t owned a Mopar before, saw this on Trade Me and bought it after selling my other cars

Build time: Six-month project – still going I’m sure

Length of ownership: 15 months

Kyle thanks: Mike Bari at AutoCare Services Ltd, my family – Frances, Connor (4) and Charlise (2), the crew at Greenpark Panel and Paint, Tony at Otahuhu Automatic Transmission Specialists Ltd, Brian at Simms Auto Electrical, Carl at C&M Performance, Gene Davys at Davys Tyres, Darryl Hanlon at Write-On Signs, Dean at STA Parts

Words: Todd Wylie

Photos: Adam Croy