What do circular saws, window wipers, in-car heaters, and mufflers all have in common besides the fact they’ll most likely be found in your garage? They were all originally designed by women! Didn’t know that did you? Then again, chances are you didn’t pick this very cool 1968 ’Cuda was designed by a woman, either.

The fact that the car’s owner, Marion Livingstone, and her husband Eric own and operate New Zealand’s most prominent Mopar workshop – West Auckland Engine Recondtioners (WAER) – also had a big

part to play in the design. The build took four years, but the story of how it all came to be goes back three decades.

“When I first met Eric he was driving an E49 Charger and racing his Hemi-powered T-Bucket. I really enjoyed driving that Charger. As time went on the Charger was sold and Eric promised he would one day buy another muscle car. Little did I know it would take 30 years to buy and four years to build,” says Marion, laughing. Those 30-odd years in the middle were consumed with children and business commitments, over which time the desire for a car continued to develop. Throughout that period the business also become known as the place to go if you’re after any form of Mopar engine, transmission, or in many cases the whole mechanical side of a vehicle build.

With all the tricks of the trade learned and numerous contacts overseas, any car Eric decided to build would always be something a bit special, although at first Eric thought this ’Cuda wasn’t meant to be, as he explains. “When I heard this car was for sale I phoned the owner and went with a friend to inspect it.

“The owner must have had a hard night as he was a bit grumpy. The car was parked over a pit that gave me access to give it a good look over, which I did. On climbing out of the pit I mentioned it had some rust and was about to say I will bring Greig [McSporran from Profile Autobody] over to check it, when the owner in no uncertain terms told us to f*** off and slammed the garage door down on us. I figured he sure did not want to sell that car.”

Not long after, Marion saw the car on the road, and reminded Eric that she still wanted it. Being a good husband, he decided to give it another shot and contacted the owner again. This time, a deal was done and the car was now Marion’s.

“We came up with a plan, and we stuck to it. I don’t like changing things along the way, as they never end up right,” Eric says. “It’s simple and functional, and that’s how it should be.”

His idea of simple must be a whole lot different to ours, as you only need to read the spec panel to work out there’s a whole lot more to this car than a big set of wheels and a shiny paint job.

The first step in the car’s build was to strip it down to a bare shell and deliver it to Kiwi Dip Strippers for a dunk in the acid tank. Once back to bare metal the car was delivered to Greig at Profile Autobody, where it would stay for some time. Greig and Eric have worked closely together on numerous projects, and they know the quality of workmanship that can be expected of each other.

While the body was in good condition, the lower rear quarters required a few rust repairs, but this was never going to be the type of car that’d be repaired using body filler. Instead, patch panels were crafted and stitched in. Greig’s sheetmetal-working abilities then turned to the rear inner guards, where the chassis rails were unpicked and moved inwards before being restitched. If you didn’t know it wasn’t factory, you’d never be able to tell, such is the workmanship.

The factory wheel arches have been refitted in such a way as to allow a rear seat to be reinstalled, as one of the key criteria for the vehicle was that it must be passenger friendly, unlike Eric’s T-bucket. Other sheetmetal work included smoothing the engine bay and enlarging the radiator area in preparation for fitting a Mancini big block radiator. To give the body shell extra strength, custom chassis connectors were welded to the underside of the body shell, although again, if you didn’t know they weren’t factory, you’d never pick it.

The paint on the other hand is certainly not factory. Based on the latest Challenger orange, the Glasurit hue features some custom ingredients which really make it pop. That same glistening orange coats not only the exterior of the shell, but the underneath and inside also.

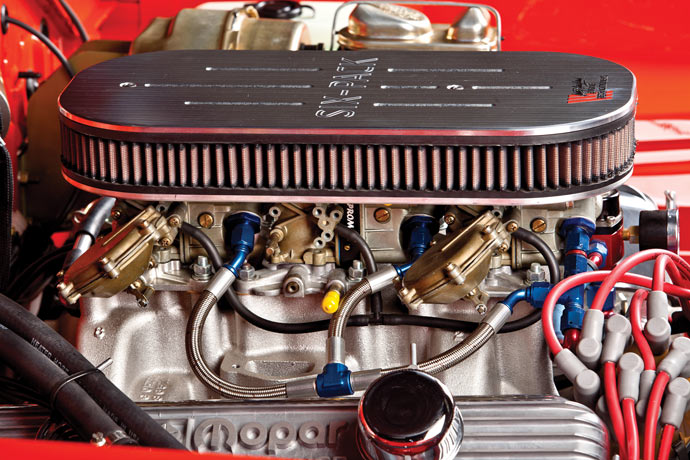

While Greig had the car, Eric was sourcing pieces for the engine which would be fitted. Marion didn’t want the car to be over the top, but wanted it to have more than enough power to match its purposeful looks. The answer was a 400 block which now displaces 496ci (8.1 litres) thanks to a 105mm stroker crank, H-beam rods and 10.3:1 JE pistons. With Eric knowing more about building Mopar motors than anyone else around, plenty of expertise has gone into the build. One of those is use of an oversized Hemi sump and modified 1/2-inch Hemi oil pick-up, mated to modified oil galleries in the block. According to Eric, and he should know, this is one of the most important things to do when building a high performance or high revving wedge motor.

Attached to the block via ARP studs are Edelbrock heads which were ported inhouse at WAER.Now fitted with stainless valves which receive instructions from a custom camshaft, the heads are high flowing. Comp Cams double valve springs along with 10-degree moly retainers and locks and Crane Gold Series roller rockers ensure the valvetrain stays intact, as do ARP fasteners which have been used throughout.

While you can’t see all the hard work and high end components used in the motor, the cool Edelbrock six-pack manifold that sits on top of it certainly lets you know the combo is somewhat special. The three carbs fitted also fall into that category.

“All three carbs are modified for the larger engine capacity,” Eric says.“Both outboard carbs have new modified billet metering plates with Holley jets rather than drillings. The centre carburettor has a modified billet metering block with screw-in E-jets for emulsion, idle feed and PVC. The rear carburettor has a modified billet base with the idle mixture screws repositioned to the side so they can be adjusted without removing the carburettor.”

It sounds like a lot of work, but as with the rest of the car, it’s been built right, and with a purpose.

Originally it was thought a rack and pinion steering setup might be required to allow room for the exhaust system, but as it transpired the TTI headers managed to fit, even with four-inch collectors on them.

From here the exhaust shrinks to a twin three-inch system with FlowMaster mufflers. Due to the tubbed wheel arches the stock fuel tank no longer fitted, so Eric had expert fabricator Frank Wigg build a custom drop tank. Incorporated into the tank’s design was room for the exhausts and Dash-8 fittings for the fuel line.

The driveline is as impressive as the engine package, and again it was all taken care of inhouse at WAER. The trans itself is a Torqueflite 727, but besides the casing there are not a lot of original parts left in it. The key features are a reverse pattern manual valve body and 3000rpm stall converter. As if that’s not enough, a Gear Vendors overdrive unit has been fitted, and essentially makes the three-speed trans into a six speed, as ratios can be changed at the press of a button.

The now considerably shorter (the Gear Vendors attaches to the end of the gearbox) driveshaft leads to a narrowed Dana 60 diff with a Truetrac LSD head and 35-spline axles. While it may all sound like overkill for a street car, at least no matter what Marion does, she’ll never be able to damage it.

The switch for the Gear Vendors has been built into the customised centre console modified by Jason Loose at Cut Loose Upholstery. Jason was also responsible for fitting the reproduction trim kit and custom-made carpets the car now wears. A B&M shifter and Grant steering wheel finish off the interior look, as Marion’s request was to keep it as original as possible. This included sending the instrument cluster to America to have it rechromed and reconditioned, as well as having Dashboard Restorations re-vinyl the dash pad.

The last step of the build was sorting the brakes and suspension, and while many Americans opt to install after-market K-members in cars such as this, Eric’s a true believer that you can’t beat how the factory builds them. As such, the original torsion bar setup remains, albeit with new componentry such as upgraded bars, strengthened lower control arms and tubular top arms. These combined with Rancho shocks and a Moog suspension kit ensure the car not only sits right but should be a pleasure to drive also.

Out the back the original rear leaf springs have been replaced with a Caltrac setup which sits on of the chassis rails and is again matched with Rancho shocks.

The wheel setup that Marion had been thinking of for the last 30 years consisted of 15×6 and 15×12-inch Weld Racing Prostar rims. The latter are fitted with massive 15×16.5×31 Mickey Thompson Sportsman Pro tyres. To stop the rolling weight of this-sized tyre is no simple task, but with a set of Wilwood Dynalite callipers and 310mm rotors hiding in behind them, it’s well taken care of. Up front are Wilwood Superlites with slightly smaller 298mm rotors.

At the time of photographing it the car was so newly finished that the sweat hadn’t dried on Eric’s forehead, and it had yet to turn a tyre in anger. One thing’s for sure though, and that’s when it does hit the road it will be a sight to see. It’s not often you see an A-body ’Cuda around, let alone one that’s as good as this, and the icing on the cake will be the smile Marion gives as she passes everything else in sight. Got to give it to the women folk, they do know how to design cool garage toys!

1968 Plymouth Barracuda – Specifications

Engine: Mopar 496ci (8.1-litre) Wedge, 1971 400 Mopar block, 105mm forged steel stroker crank, JE custom forged pistons, 10.3:1 compression ratio, H-beam con rods, moly file fit rings, enlarged Hemi sump, modified ½-inch Hemi oil pick-up and block oil galleries, Rollmaster timing kit with Iwis chain, ARP main studs, billet solid flat tappet camshaft (110-lobe separation, Adv duration In 289 Ex 291, duration at .050 In 255 Ex 258, valve lift In .541 Ex .536), Johnson solid lifters, blueprinted and balanced, Cometic multi layer steel head gaskets, ported Edelbrock alloy heads, 54.3mm inlet valves, 46mm stainless exhaust valves, Comp Cams double valve springs, 10-degree moly retainers and locks, Crane Gold Series roller rockers, Custom 3/8-inch moly pushrods, ARP head stud kit, Mopar Performance rocker hold down kit, polished Mopar Performance rocker covers, Edelbrock Mopar alloy six-pack manifold, three Holley carburettors, dash-6 braided fuel lines, billet air cleaner with a K&N air filter, Aeromotive electric fuel pump with 1/2-inch shut-off tap and filter, Aeromotive fuel pressure regulator, dash-8 fuel lines to the regulator and dash-6 into the modified Holleys, alloy drop tank, Mopar Performance electronic distributor, modified advance curve, MSD 6AL, MSD Blaster coil, MSD leads, TTI coated two-inch headers with four-inch collector, three-inch exhaust system, FlowMaster mufflers, Mancini custom alloy big block radiator, two 356mm electric fans, deloomed and smoothed engine bay

Driveline: Torqueflite 727 transmission, competition clutches and bands, extra clutches, steel spline front planetary, bolt-in sprag, billet rear servo, solid front servo, modified servo and clutch spring kit, 4.2 KD lever, reverse pattern rear band apply, manual valve body, deep sump and oil pickup, custom 3000 stall converter, SFI flex plate, 11mm Hemi converter bolt kit, narrowed Dana 60 diff, 35-spline axles, Truetrac LSD, Gear Vendors overdrive unit, custom driveshaft

Suspension: Upgraded torsion bars, strengthened lower control arms, tubular top suspension A-arms, Rancho adjustable shock absorbers, full Moog suspension kit, factory sway bars, reconditioned power steering box with a firm feel kit, Caltrac inboard rear suspension system

Brakes: Wilwood Superlite four-pot front callipers, 298mm rotors, Wilwood Dynalite four-pot rear callipers, 310mm rotors, aluminium hubs, braided lines, internal hand brake

Wheels/tyres: 15×6- and 15×12-inch Weld Racing Prostar rims, 195/70R15 Hankook tyres, 15×16.5×31 Mickey Thompson Sportsman Pro rear tyres

Exterior: Custom chassis connectors, custom tubs, narrowed rails, smoothed engine bay, customised Glasurit paint

Interior: Full retrim, painted seat frames, modified rear seat, custom carpets, Grant Mopar Tuff steering wheel, B&M Black Diamond ratchet shifter, restored gauges, Auto Meter shift light, tachometer, oil pressure gauges, Pioneer head unit, Kicker four-inch front speakers, Kicker 6×9-inch rear speakers, Sony amplifier

Performance: Approx 580-600hp (433-447kW), dyno tune not completed until after magazine print date)

Marion Livingstone – Owner Profile

Car club: Wheels Inc

Age: Younger than Eric

Occupation: Self employed – West Auckland Engine Reconditioners

Previously owned cars: 1972 E49 Charger, 1923 Hemi T-bucket

Dream car: The next one

Why the ’Cuda: When I first met Eric he was driving an E49 Charger and racing his Hemi T-bucket. I really enjoyed driving that Charger. As time went on the Charger was sold and Eric promised he would one day buy another muscle car. Little did I know it would take 30 years to buy and four years to build!

Build time: Four years

Length of ownership: Four years

Marion thanks: Greig from Profile Autobody, Wayne from Western Auto Electrical, Jason Loose from Cut Loose Upholstery, Frank Wigg Fabricators, Kevin Marcroft Metal Polishers, Mark Stokes Vehicle Certification, Kerry from Pit Stop Henderson, Martin for all the machining and hours of help and the rest of the staff at WAER

Words: Todd Wylie Photos: Adam Croy