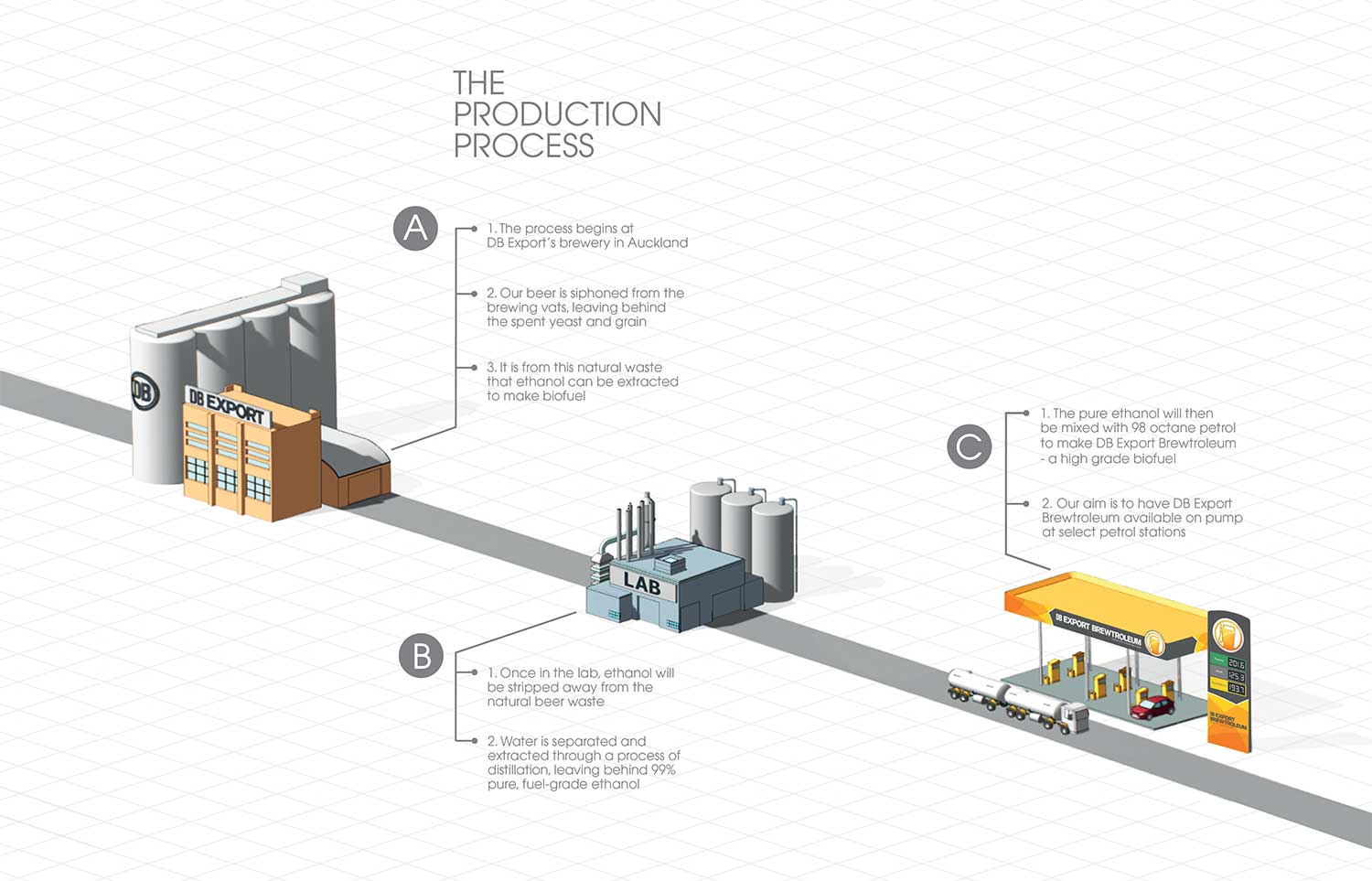

Us Kiwis love a cold one, and we could soon be saving the planet every time we pop the top off a beer. DB Export have announced plans of an attempt at producing a commercially viable biofuel, based on the by-products of beer brewing.

By using ethanol — derived from beer production — and mixing it with regular petroleum, they hope to have their ‘Brewtroleum’ ready by July 2015. These biofuels emit less carbon than petrol when burnt, so it may not be long before we have a legitimate excuse to buy a box.

The brewing process leaves dregs of yeast slurry, which tests by DB Export and independent specialists have found can be stripped of ethanol. This can then be distilled and blended in a 10:90 ratio with 98 octane petrol to create an E10 (10-per-cent ethanol) biofuel.

“Brewtroleum presented the opportunity to take the natural by-product of the brewing process and turn it into something that can genuinely help the environment,” said Sean O’Donnell, DB Export’s Head of Domestic Marketing. “What’s more, men can help to save the world just by doing what they already love — drinking DB Export.”

The first sample of DB Export bioethanol will be ready for testing in a few weeks, and, if it is successful, Brewtroleum will be made available through one of the country’s major fuel retailers. We’ll be keeping an eye out for further news — we’re all for more reasons to feel good about drinking beer!