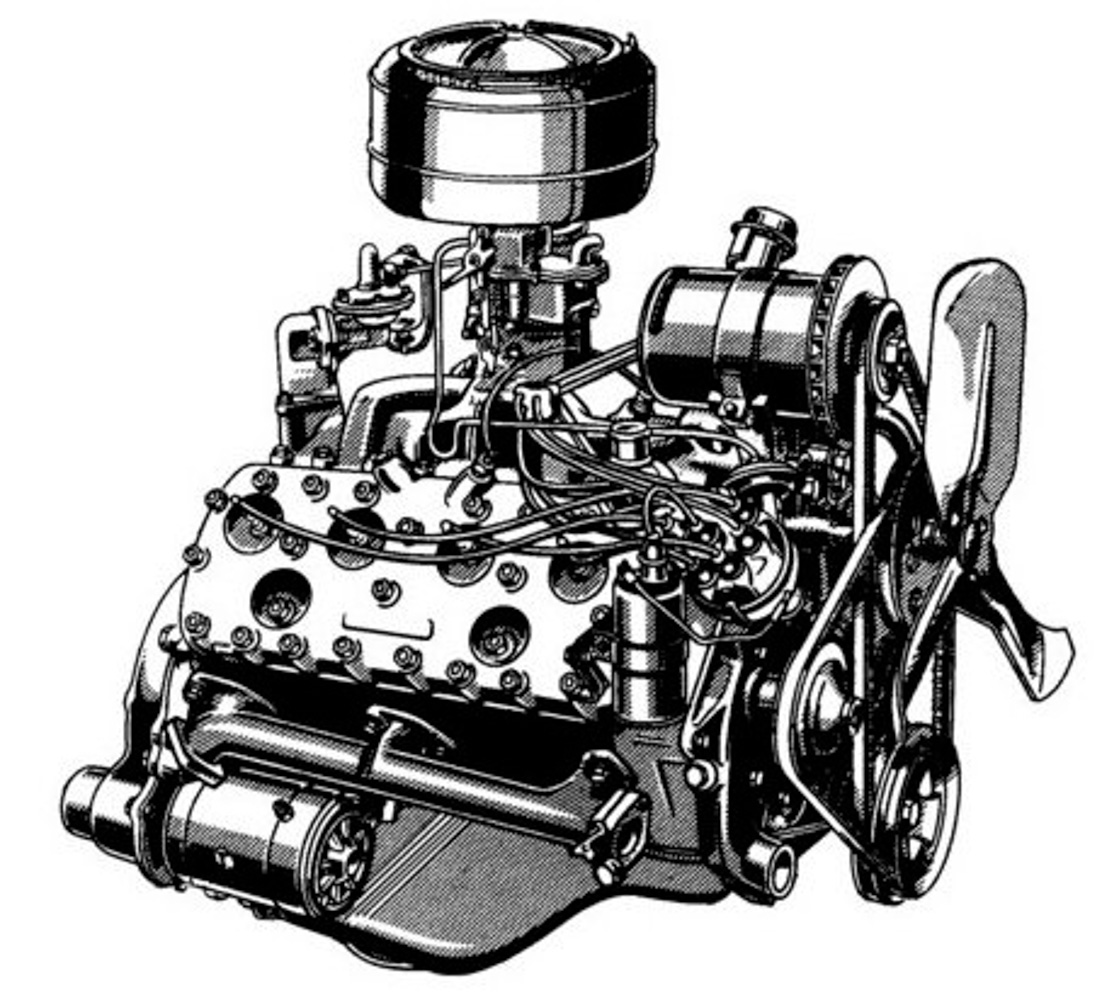

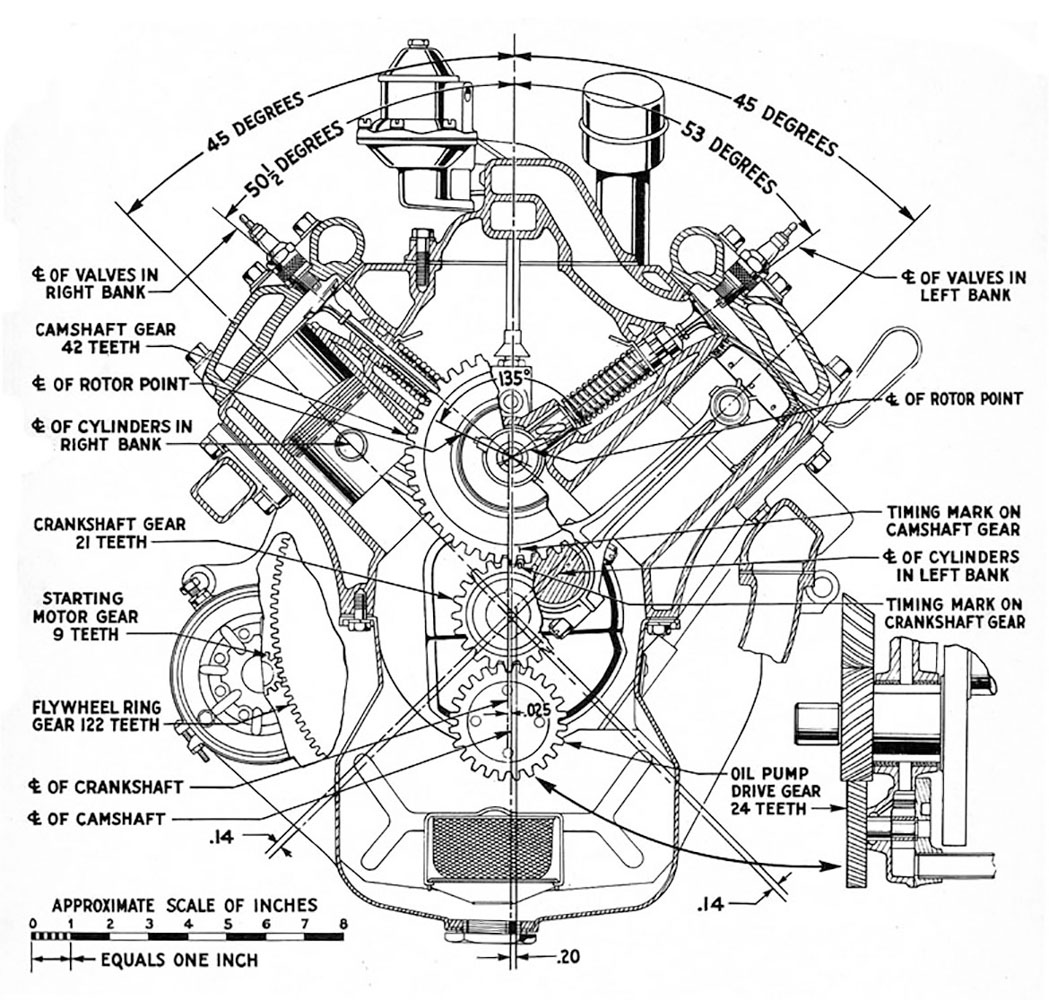

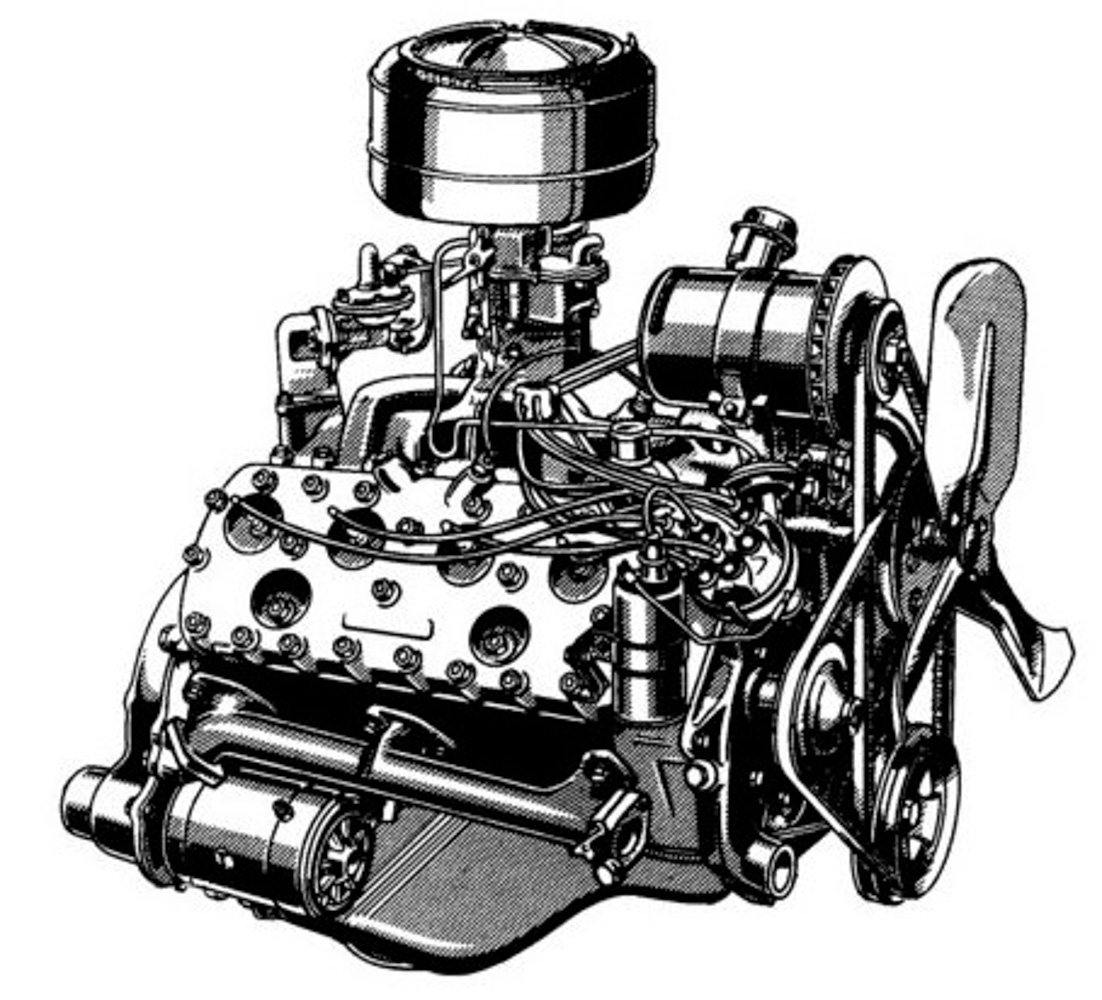

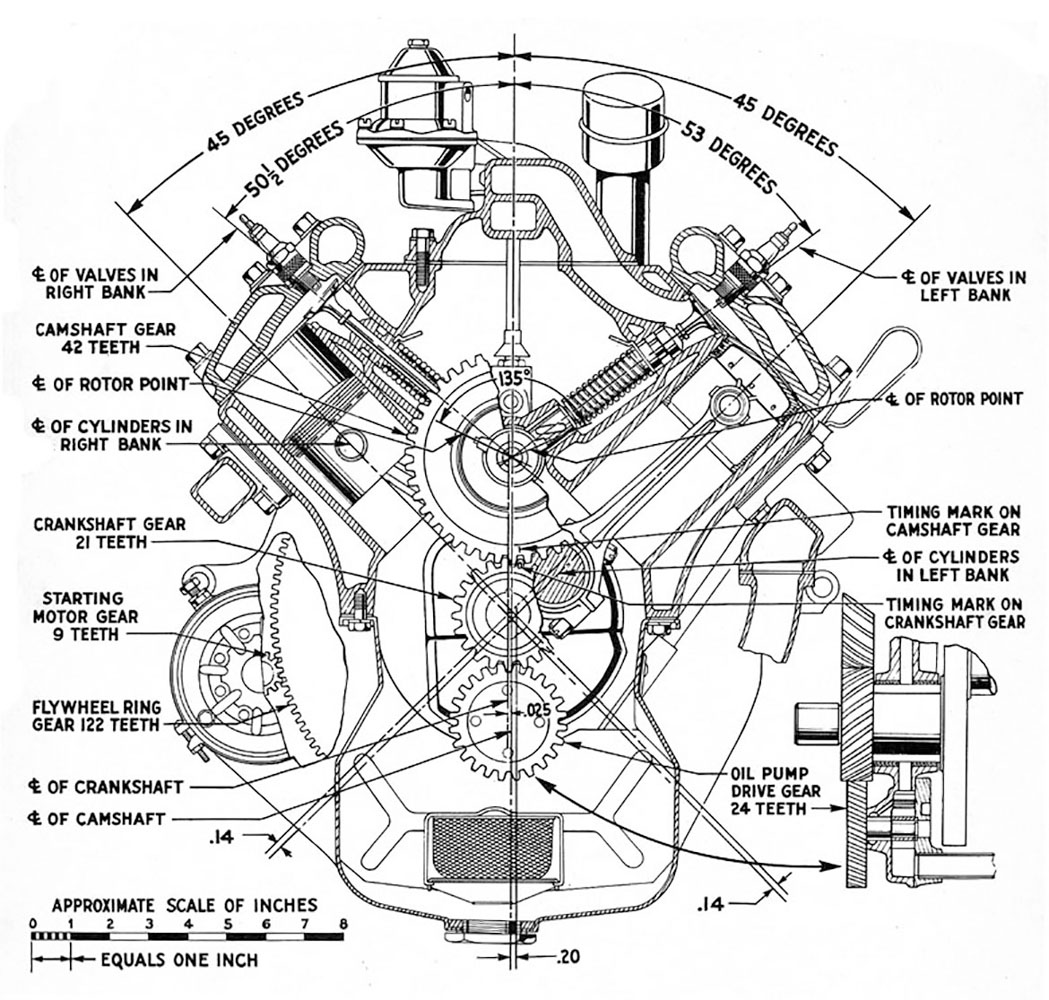

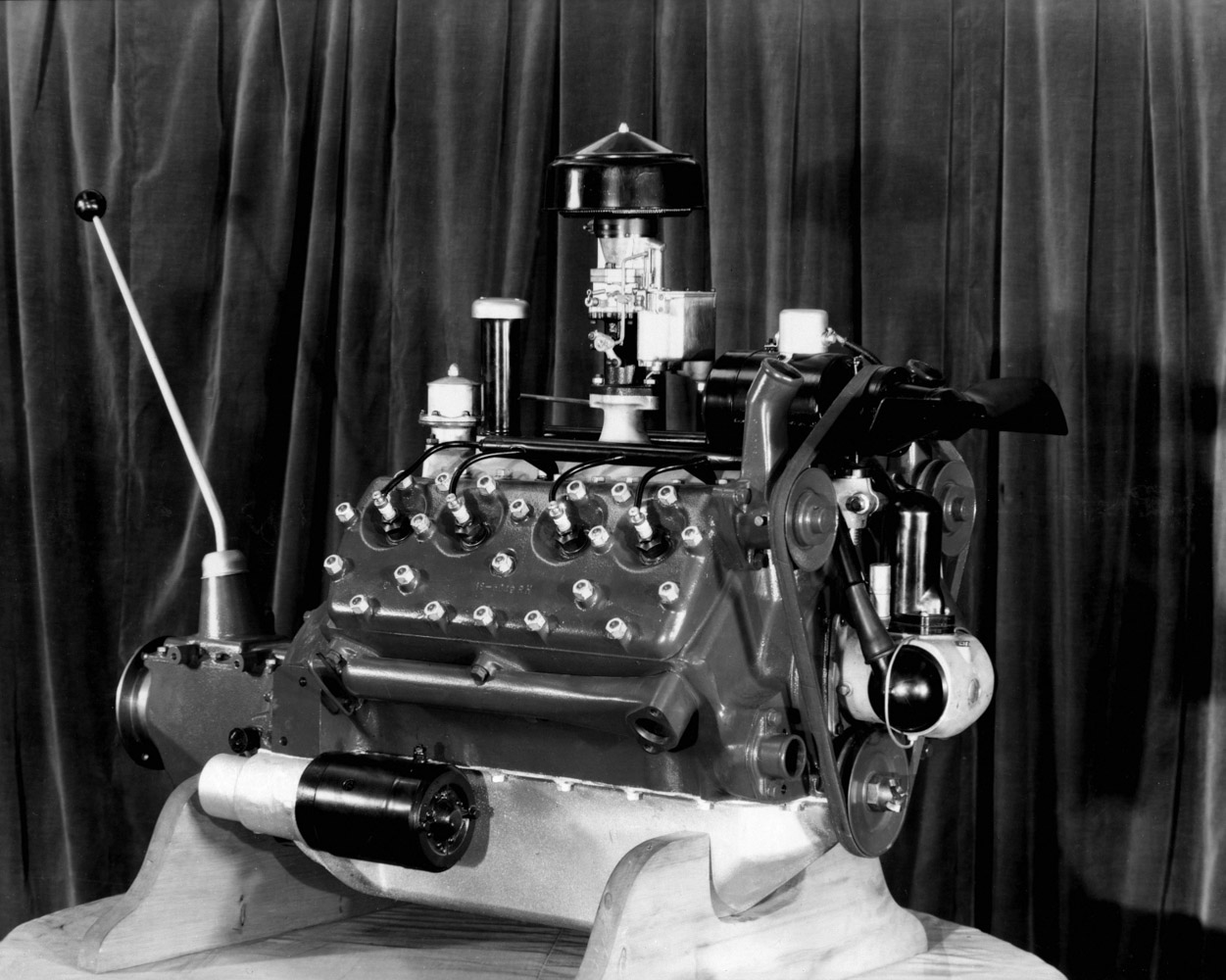

Ford’s flathead V8 is the forefather to the entire American V8 scene, with its bang-for-buck performance at the time of its launch unlike nothing else the world had ever seen. It was introduced in 1932, and designed for production by Carl Schmaltz, Ray Lard, and Mil Zoerlein. The design was simple, with poured babbit-style main bearings, 21-head studs, one belt for the generator and fan, and two water pumps.

The pioneering flathead V8s did have their flaws, though — cracking was common, as was oil starvation when turning the car around hard corners, leading to seized crankshaft bearings. Check out the timeline of the famed engine’s production below:

1933: Aluminum heads and higher compression give an extra seven kilowatts, while ignition and cooling improvements help reliability.

1934: New dual-downdraught Stromberg 40 carburettor and new intake manifold adds an additional seven kilowatts. Bottom end benefits from an industry-first and a cast-alloy steel crankshaft.

1935: Carburettor replaced with Stromberg 48, and the camshaft is updated. The engine design also benefited from improved crankcase-ventilation system.

1936: Carburettor changed once more, this time to Stromberg 97 on all V8-85 (85hp/63kW) engines. Cooling capacity and radiator surface area increased, to aid with cooling. LB block gains separate main bearing inserts, while babbit-bearing mains are retained on all other motors.

1937: The V8-60 enters production as a response to European displacement taxes, and British taxes based on bore size. The V8-60 is notable by its 17-head studs, instead of 21. The V8-85 gains a larger water pump and main bearing inserts, as well as new cast alloy-steel dome-top pistons.

1938: Ford switches to a Holley carburettor, from the Stromberg 97.

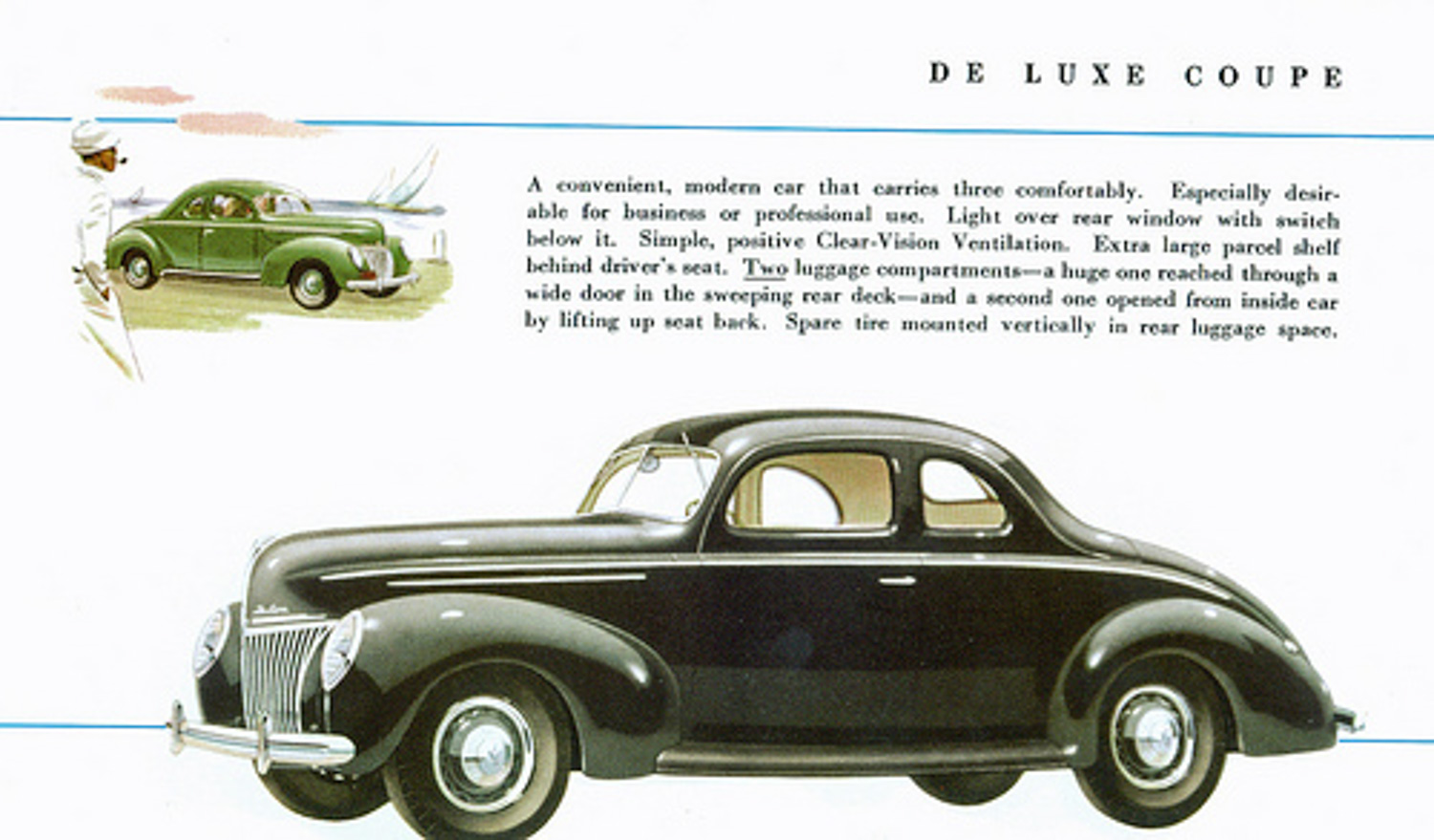

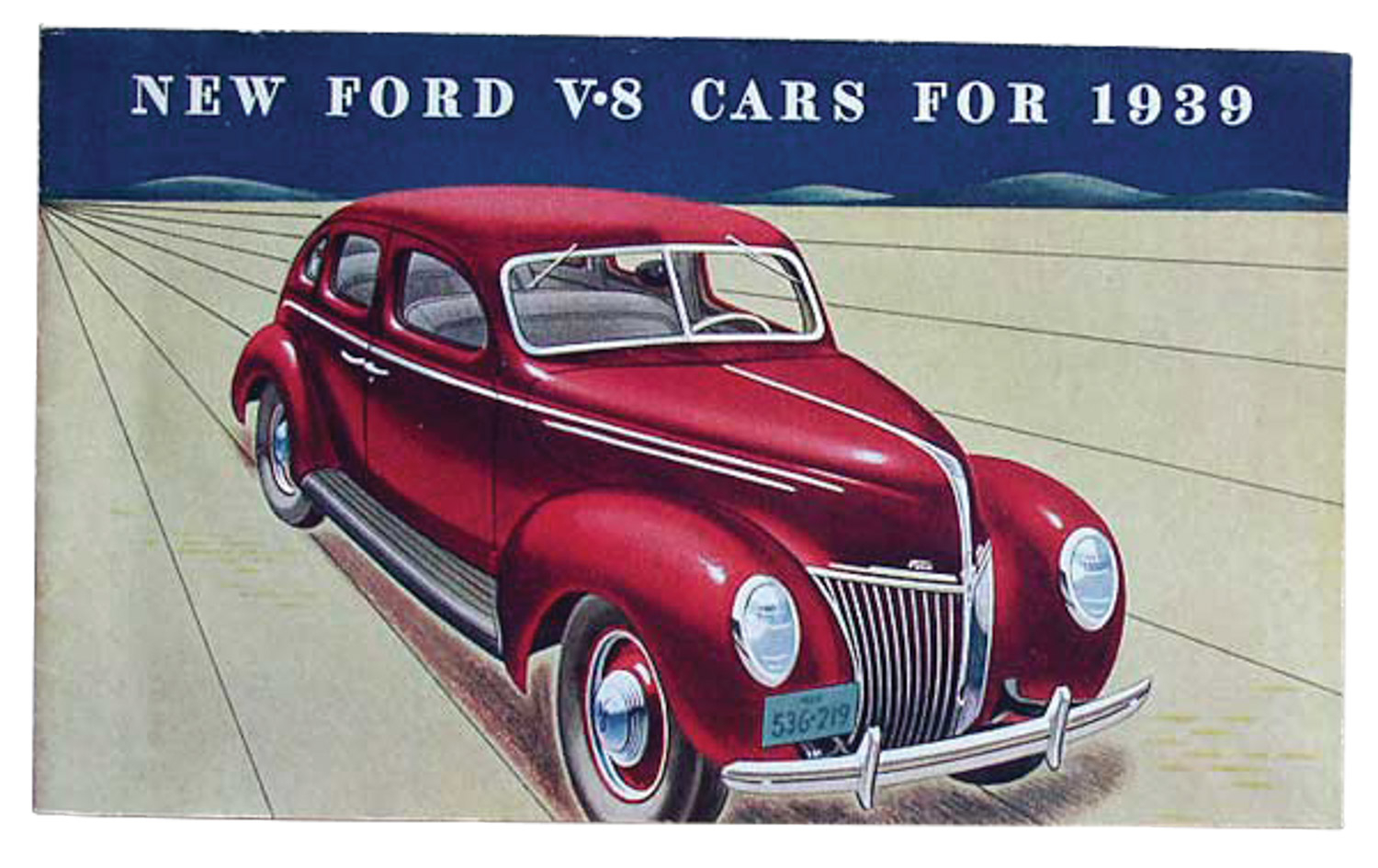

1939: A Ford-built dual-downdraught carburettor helps pump the V8-85’s torque output to 210Nm. Head stud count is increased from 21 to 24, and the main journal size is once more increased. Mercury used an overbored flathead, displacing 3.9 litres (239ci), which also gains a strengthened crank, rods, and other internals.

1940: The V8-60’s last production year. Ford produces ten alloy blocks for experimentation purposes.

1942: Power now rated at 67kW (90hp), despite no mechanical changes. Flat ‘crab’ distributor cap with separate ignition coil introduced.

943–1945: Ford production diverted towards World War II effort.

1946: Ford gains Mercury flathead, with unique alloy pistons, bearings, larger rod journal size, and pressurized cooling system. The ‘V’ angle between valves (between driver and passenger sides) is reduced from 101.5 degrees to 100 degrees, to reduce cracking. New one-piece distributor cap replaces old two-piece design. Fan shifted slightly upwards, to reduce water spray onto the engine in wet weather.

1948: New 5.5-litre (337ci) flathead introduced for F7 and F8 trucks.

1949: The 5.5-litre flatheads became available in the Lincoln range, with increased compression. Mercury V8 stroked, increasing power. Major mechanical revisions are also made in 1949. The bellhousing is now cast as a separate unit to the block. Oil pump and coolant systems are updated. Improvements are made to the valve guides, and intake and exhaust systems. Main bearings are upgraded, via stronger caps and improved webbing.

1950: Piston design revised to eliminate piston slap when cold, and camshaft revised to minimize tappet noise. Three-blade fan replaces old four-blade design.

1952: Mercury 4.2-litre (255ci) flathead increases compression, taking power to 93kW/125hp. Revised cam profile takes F-series truck power rating to 79kW/106hp.

1953: Ford’s 50th anniversary also marks the final year for the flathead in the USA, replacing it with the overhead valve (OHV) style Y-block.

This article was originally featured in a previous issue of New Zealand Classic Car. Pick up a copy of the edition here: