data-animation-override>

“Over the years, many kit-car manufacturers have come and gone. One that does not deserve to go is McGregor, but it may be another victim of the Christchurch earthquakes. Though they were several years ago, their repercussions are continuing long after most of the aftershocks have subsided”

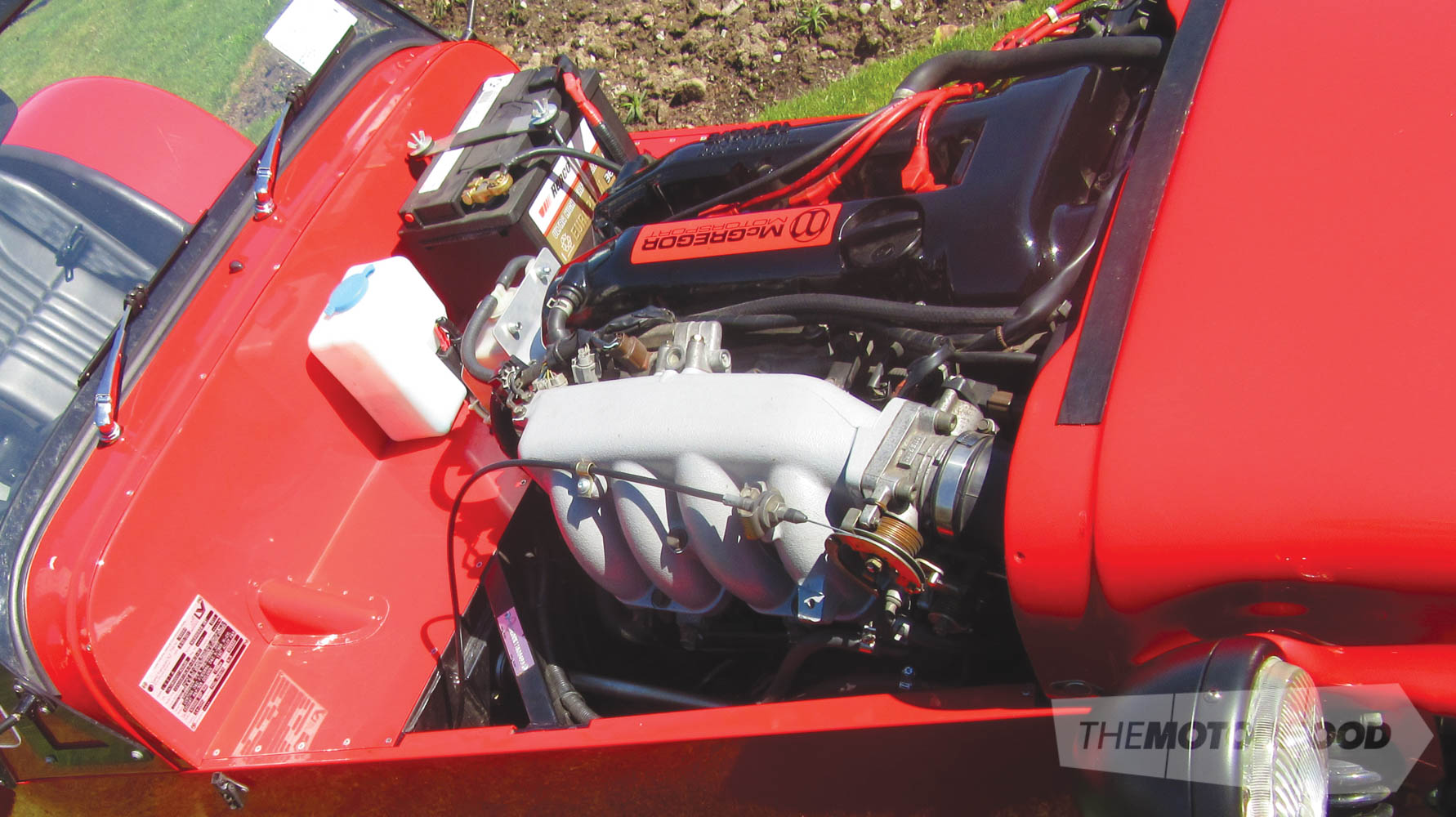

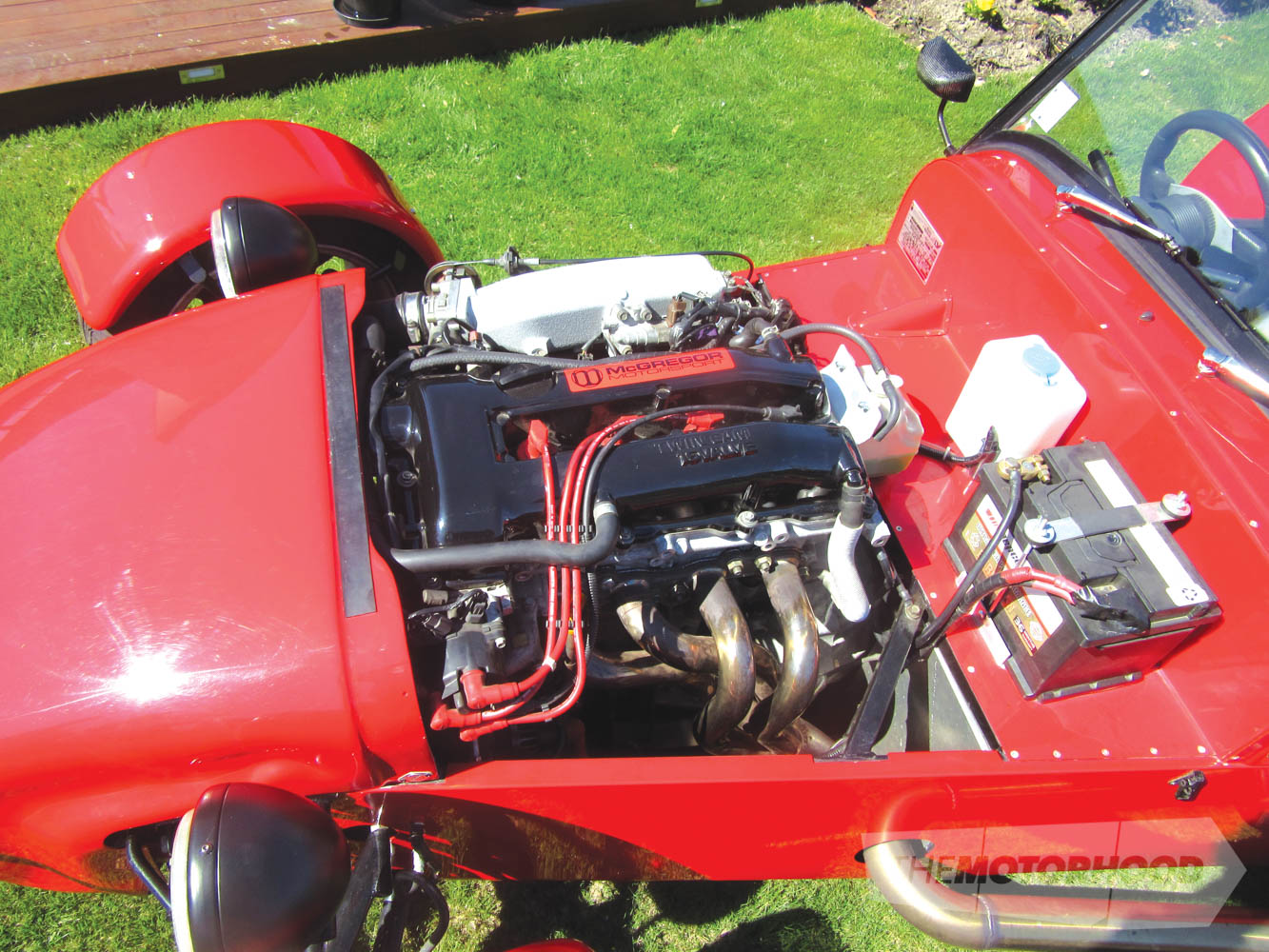

When John McGregor first started his company back in 2001, this car was never intended to be just another Lotus 7 replica; although it would capitalize on the simplicity and cost-effectiveness of the original Lotus design, it would be a different car. Once three or four McGregors had been produced, John decided to do a bit of quality control by comparing his car with an original Lotus 7. Using contacts in the Lotus Club, he found somebody who was prepared to lend him a genuine Series 2 Lotus 7, from which he was able to take several measurements. John had already increased various dimensions in his car, subtly but very effectively, enabling it to be driven by those greater than 1.8 metres tall and wearing street shoes. Although John McGregor played a huge part in getting the company up and running, this story continues with the contact and later good friend who owned the original Series 2 Lotus 7.

Lotus fan

Robert Snow was not only an importer of hi-fi electrical components but also a huge Lotus fan. At the time that he met John, he owned two Lotuses: a ’66 Series II 7 and an Elan+2. When he heard about the McGregor, he wanted to be involved and many hours were spent in John’s factory in Aranui, Christchurch, with Robert giving his time when he could spare it. This arrangement worked well for several years. However, during 2005, John’s wife started quietly informing her husband, now in his mid 60s, that it was time to seriously consider retirement. Eventually, he agreed, and, in July 2007, he sold the company to Robert Snow, who had offered to buy it in partnership with Mark Roberts. Safe in the knowledge that the company was in good hands, John hopped in his Rover V8–powered McGregor and retired to the North Island.

Combined knowledge

Robert and Mark were a natural team, with skills that complemented each other and the future direction of the company. Robert, having brought his knowledge of sourcing good deals on hi-fi parts, was able to put his skills to work sourcing parts for the cars at a good price. Mark already had a lot of experience doing fabrication work, so he was able to look at ways of fine-tuning and simplifying production and improving the design.

By 2009, they had outgrown the Aranui workshop and moved to bigger premises on Maunsell Street, in Woolston. The concrete floor was exceptionally flat, which made it ideal for setting up all the jigs for kit-car production. By now, McGregor Motorsport had become known as the go-to place for repairing or restoration of classic cars, especially those made by Lotus. At one time in the factory, there was a Lotus 18, Lotus 20, Lotus 22, and Lotus 23b sitting beside an Elan and a Series 4 Lotus 7, not counting various McGregors being constructed, repaired or serviced.

It was not uncommon to see kit cars from other 7 manufacturers sitting on their hoists either, including Frasers, Leitchs, and even a very rare Wilco 7. Business was humming, with a steady supply of McGregor kits heading out the factory doors.

It was in this factory that work started on a second kit slated for production. Once again, they turned to Lotus for their inspiration, except, this time, it was a Lotus 11 — for starters, a one-off 11 that had been handmade in Wellington and was purchased in an almost driveable state. However, Mark decided that it needed a lot of development before it would be allowed to carry the McGregor name, and set about designing a new chassis for it based on the original Lotus design. Eventually, it was deemed ready, and the first kit was built and sold; however, that would be the only kitset 11 to leave the factory. Previously, John McGregor had built an 11 for himself, but based on his 7 chassis design.

Devastation

At 4.30am on September 4, 2010, the first major earthquake occurred in Christchurch. Fortunately, apart from equipment falling off shelves and making a serious mess, nothing was really damaged. It was a different story at 12.50pm on February 22, 2011, when the next big earthquake struck. This time, it was quite a terrifying experience, with the factory floor literally rising and cracking beneath their feet: Robert was thrown sideways several metres. Not only that, but also both Mark’s and Robert’s homes were damaged beyond repair. Although they did not know it at the time, the quake was the beginning of the end of McGregor Motorsport.

It took a while, but eventually they were allowed back into the factory and could salvage what was still usable. That was the easy part. What followed was a long and expensive battle with their insurance companies over their homes as they struggled to get the factory back up and running. Eventually, Robert decided to bite the bullet and buy a new factory around the corner in Broad Street. However, there were many months without any income before production could restart.

When the pair did get the start-up underway, they found that not only had the Christchurch landscape changed but also the city had a whole new economic focus. People no longer had disposable income to spend on hobby cars. Work on specialist cars also dried up as people struggled to pick up the pieces of their lives. Rather than wallow in depression, Mark and Robert used this time to re-evaluate the McGregor design. Though it already had race-car handling, Mark believed that it could still corner better. The Sierra diff was ditched in favour of a Subaru one, which was easier to get hold of and had a good range of ratios, as well being limited slip.

Laser cutting had now become very cost-effective for producing specialist steel parts. This enabled work to be done on a new design for the front and rear suspension, and also allowed Mark to redesign the transmission tunnel and gain another 50mm of space across the width of the cockpit, along with greatly improved torsional rigidity.

Despite all this development, though, there were still insufficient orders coming in. By now, Robert was well past the normal retirement age and alot of money was being poured into the company, with no real return. Midway through 2014, the tough decision was made to sell the factory, and McGregor production ground to a halt in January of 2015. Of the 40 or so McGregor cars that were manufactured, five of them had the new chassis.

Continuing support

Today, the McGregor website remains active so that existing customers who are still building cars can receive support and any specialist parts to complete their projects, but no further cars have been made. Mark continues to work as a fabricator, albeit for another company, while Robert is enjoying retirement just outside Christchurch in West Melton. He remains positive about life eventually returning to normal in Christchurch and is confident that, at some stage in the not-too-distant future, people will once again want to build their own unique sports car.

Robert hopes that it will be a McGregor; consequently, he has retained not only the ‘McGregor’ name, but also all the engineering drawings and data, jigs, moulds, and plans outlining all the improvements that have been made to the original design. These are now for sale, and Robert can be contacted via the McGregor website.

Hopefully, one day, this fine little car will be once again available to the public.