Heading into a final race-series round with a 272-point lead after winning nearly every race contested that season is not easy in a series as competitive as the BMW Race Series, let alone if you’re driving what was effectively a brand-new race car at the season opener. But, perhaps it’s simply vindication for the extremely well-planned and executed race-car project produced by the small team involved.

The project was spearheaded by owner/driver Andrew Nugent, who is something of an old hand in the BMW racing ranks in New Zealand. “When I was young, I raced cars and then powerboats.” But he hadn’t raced in a long time when the BMW E30 Series was first considered, so, “Myself and a friend, Paul Mill, decided to build two, and we had a whole lot of fun,” Andy explains.

Three seasons of racing E30s were followed by three seasons of racing an E46 M3 in the open class. Andy managed to place third in the 2011 championship, though the E46 was underpowered and not as competitive as he would have liked. It was time to build one last car, something of the highest calibre that was capable of winning the championship: “I was always keen to move up to a car that could compete at the front of the field, so I decided to build a new car using what I had learned from racing in the series.”

Unlike most of the builds we showcase, which have snowballed into the end result, what you see here is what was planned from the outset. This is because the team put in a ton of prep work, planning and designing every component before even beginning to touch any steel. Even after the bare chassis was sourced and delivered to Neil Allport Motorsports, it was a further six months of designing before the team touched it. Talk about a well-planned-out project!

Matt Houston was charged with translating Andy’s ideas onto paper before Neil Allport Motorsports could turn concept into reality. But, before all that could happen, a decision needed to be made about what shell to base the project on. BMW rules dictate that the shell must run a factory engine option. As you can see, the E92 platform was chosen — why? Because it came with a six- or eight- cylinder engine from factory, which gave the team options.

The rest of the rules within the BMW Race Series are fairly loose, with the breakout lap times ensuring competitiveness — which is a race-car builder’s wet dream. No, not the breakout times, but being able to build a car with only a basic list of rules to adhere to.

“Basically, we had a clean sheet of paper. It’s been a great engineering project from my point of view; we probably slide under the radar a little when it comes to circuit cars, because, obviously, my background is in rallying. But, as I said to Andy at the start, a car’s a car — you just have to tune it up to run on the surface you want, the principles are all the same,” Neil Allport explains.

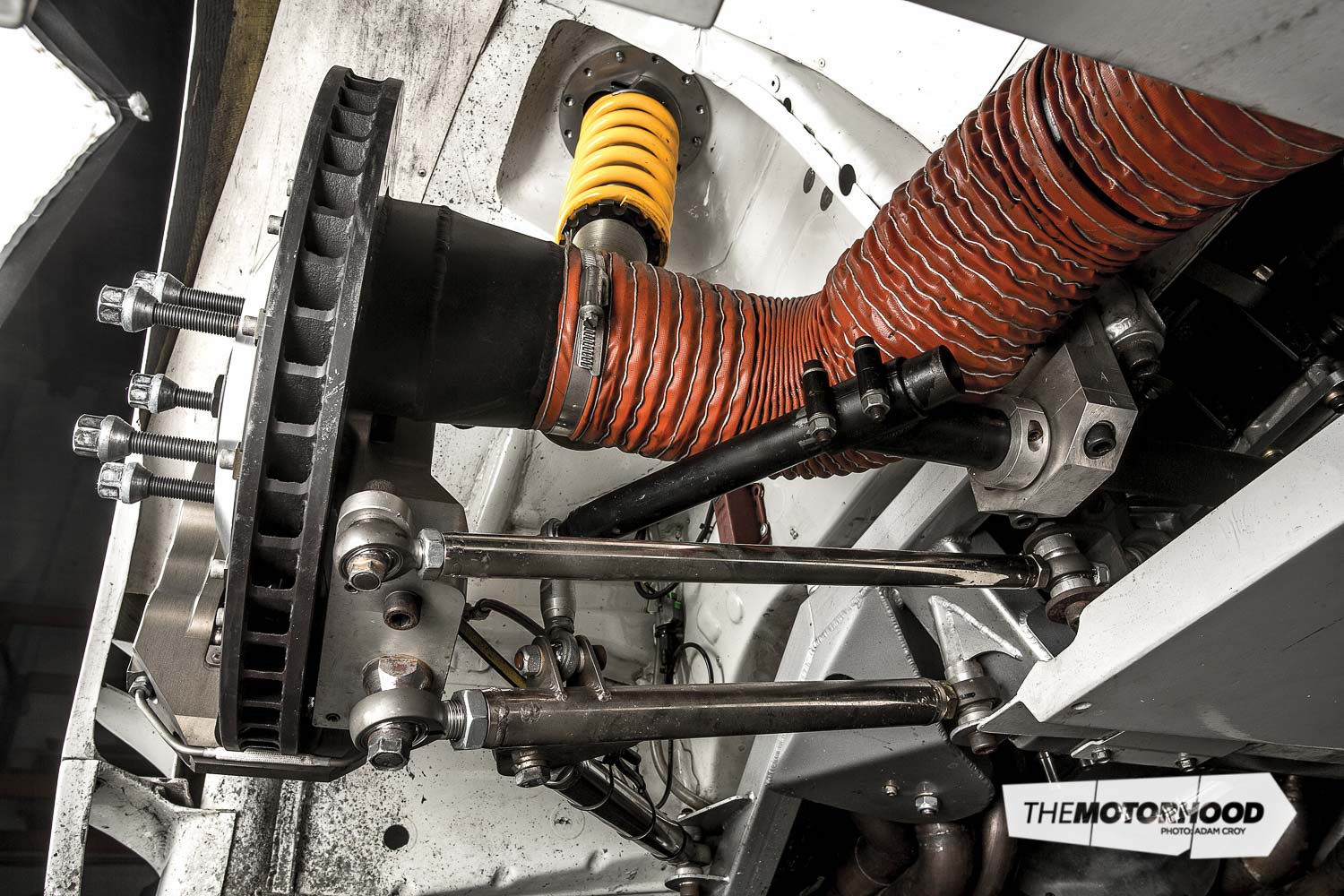

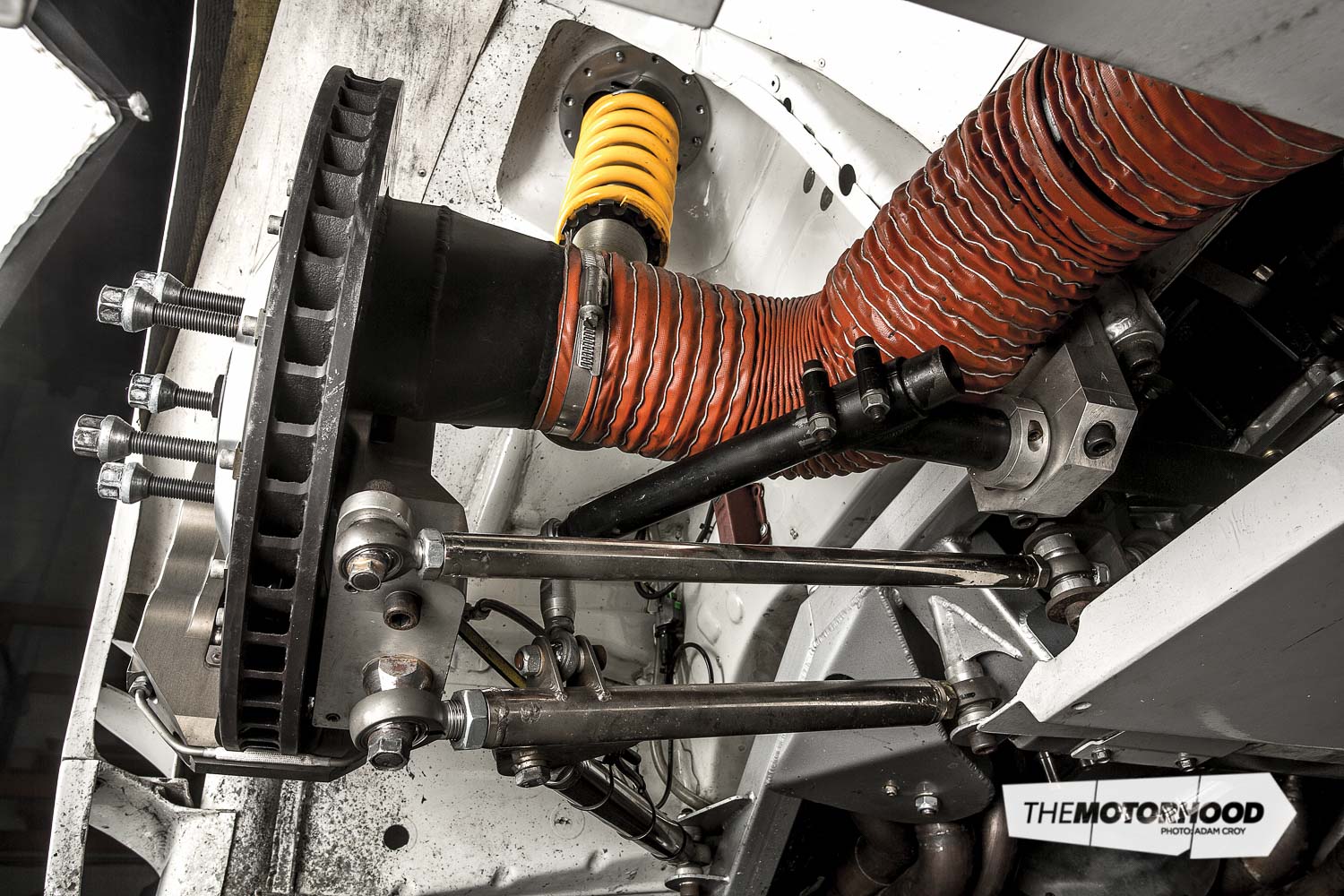

A no-compromise project like this has meant that each and every component has been designed to maximize the E92’s performance, within the rules. The subframes were remanufactured to shift pickup points and correct the roll centre, while also shifting the engine to its ideal position — as low and as far back as the uncut firewall allows.

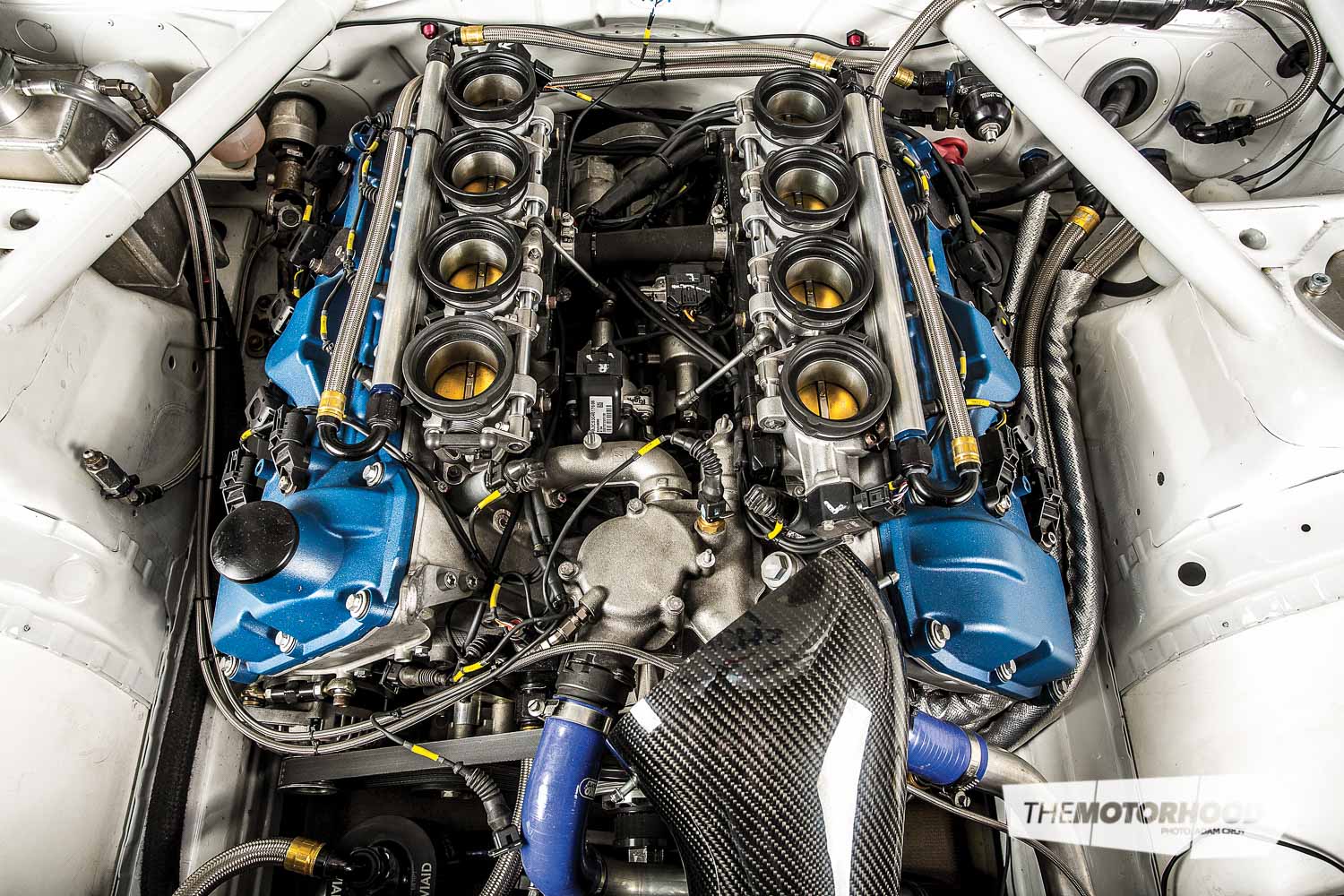

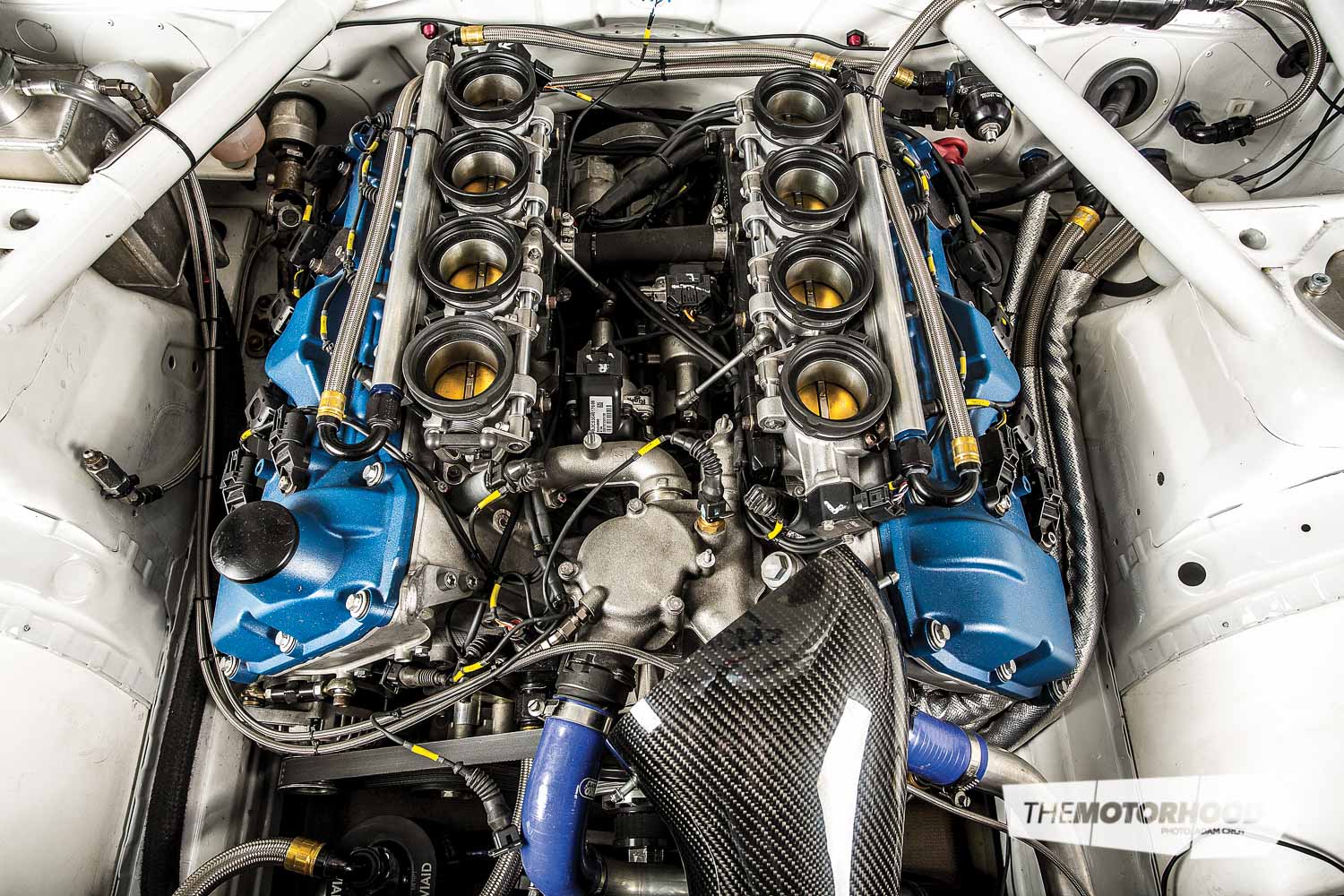

Even the choice of engine was an educated and calculated one. As we mentioned, the E92 came factory with a six- or eight-cylinder option, and the team originally planned to run a turbo six-cylinder, to the point that an engine was purchased. But, ultimately, it was decided to swap to the V8.

“It looked like we were going to be pioneering with the six-cylinder turbo, [but] the rules weren’t clear enough about what configuration we could use, and we didn’t want to build it only to find we were not able to run the car. There were a few Dinan-built V8s running locally, and they seemed reliable. I priced up building something locally or just importing a Dinan-built engine, and the imported engine just made sense financially,” Andy says.

The Dinan stroker S65 increases capacity from 4000cc to 4600cc. Controlled by a Life ECU, the combination will not shut down a dyno, but that was never the intention, a philosophy Andy learned a long time ago during his boat-racing days.

“I would rather be down on power but always be there at the end,” he says. “I’m very happy with how the V8 has performed; we are not stressing the engine, and it’s been really reliable.” Neil is also a firm believer that the team made the right choice in going to the V8: “We don’t have the most power out there, there are certainly cars with more power and more torque, but what we have managed to come up with is a package that is very, very easy to drive. You can just get in it, grab it by the scruff of the neck, and it just does everything you need it to do. And, to me, that is paramount. I don’t buy into that ‘more power’ argument; it has to have the whole package.”

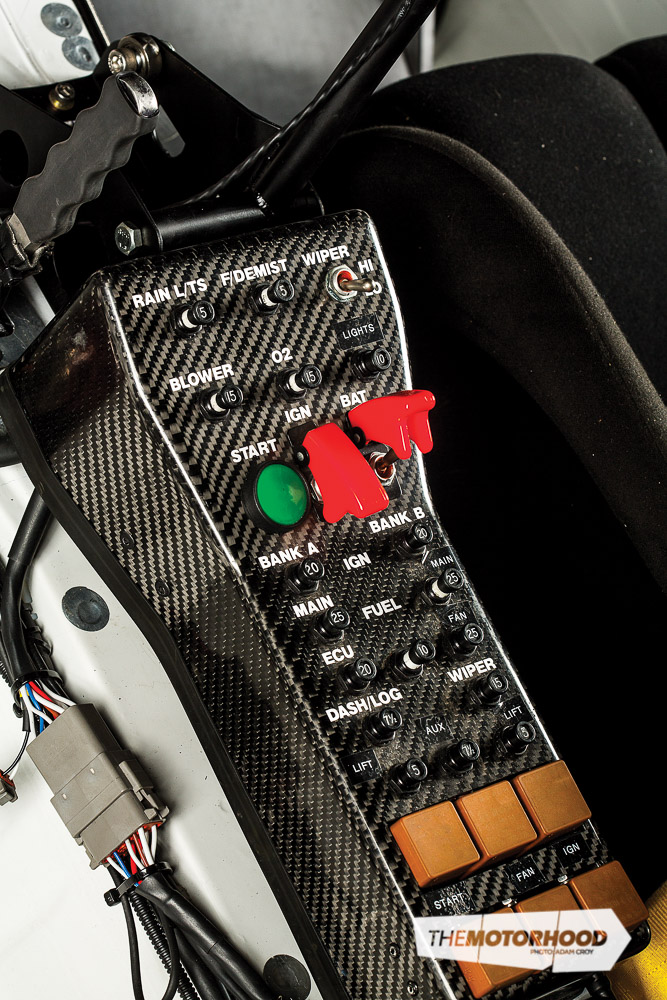

The cornerstone of that package has been the electronics, based around the MoTeC 125 data-logger dash and Life Racing ECU. While the car has proved reliable, the data logging has meant anything like the adjustable ABS or traction control can be dialled within a lap, and Andy can use the data to improve himself as a driver. All that means that he’s learning not only a new car, something much faster than anything else he has ever driven, but also a new way of perfecting his skills as a driver.

Right off the bat, the car ran smack on the breakout times for the bracket, and it’s proved to be a class act, with few others able to touch it. But, just as it drove Andy to up his game three years ago, it has driven others in the series to up their game, too. There are new cars appearing, and, at the last race, five cars were running 1.08s at Hampton. Andy knows that next season will be a much tougher challenge — so it’s a good thing there is still plenty of development left in the chassis then, eh?

However, first things first: there is the final meeting of the championship to contest to see if, after all the years of building and planning, the E92 can complete its intended job. Good luck to Andy and the team on that quest, and hats off to them for building such a world-class car here on home soil.

2009 BMW M3 (E92)

Heart

- Engine: BMW S65, 4600cc, eight-cylinder

- Block: Dinan 4.6 stroker kit, Dayley dry sump

- Heads: Dinan cams

- Intake: Factory air-box fed by ram filter

- Exhaust: Dinan headers, Adrenalin R mufflers

- Fuel: ATL fuel cell, Bosch 044 fuel pumps

- Ignition: BMW Motorsport NGK plugs

- ECU: Life Racing

- Cooling: Adrad radiator, Mocal Laminova water-to-oil cooler

Driveline

- Gearbox: TTi six-speed

- Clutch: Alcon twin-plate

- Flywheel: Custom

- Diff: BMW M3 Motorsport

Support

- Struts: MCA coilovers, King springs

- Brakes: Bosch ABS system; (F) Alcon six-piston calipers, 380x35mm two-piece rotors, Ferodo pads; (R) Alcon four-piston calipers, 345x28mm two-piece rotors, Ferodo pads

Shoes

- Wheels: 18×9.5-inch Enkei PF01

- Tyres: Pirelli P Zero

Interior

- Seats: Sparco Circuit II

- Steering wheel: Sparco, quick-release hub, power-assist

- Instrumentation: MoTeC 125 dash

Exterior

- Paint: Factory white by Mills Collision Repair

- Enhancements: Kit designed by BM Racing and manufactured by Motorsport Composites

- Power: 429kW (575hp) at the flywheel

Circuit times

- Hampton Downs and Pukekohe: 1min 8s

Driver profile

- Driver/owner: Andrew Nugent

- Age: Somewhere over 50

- Location: Auckland

- Occupation: Businessman

- Build time: Two years

- Length of ownership: Three years

- Thanks: Neil Allport for the execution of my vision and plan and ongoing support, Matt Houston for the layout design, Richard Moss at Motorsport Electronics for the electronics and continuing support, and Michael Gwillam at Motorsport Composites for the beautiful job on the panel/bodykit build. And to our other partners, Buro Seating (the best office chairs in the universe), Sunoco Race Fuels, and Eat Your Books

This article originally featured in the June 2016 issue of NZ Performance Car (Issue No. 234). You can grab yourself a print copy or a digital copy of the mag now: