Just building your engine the way it was supposed to be will unleash smooth power and longevity, then you can port and polish to gain even more

By Jim Richardson

You occasionally hear petrol heads tossing around the term ‘blueprinting’ when referring to an engine they have assembled, and have sometimes altered significantly.

What they are probably trying to say is that their engine was carefully machined to optimum tolerances and balanced — probably for racing. But that isn’t what the term meant originally. You see, in the 1950s when US stock car race cars really had to be stock, the racing teams would go to the factories and rummage through the parts bins until they found components that were closest in tolerance to the original blueprint developed by the engine’s designers.

Producing the best possible engine

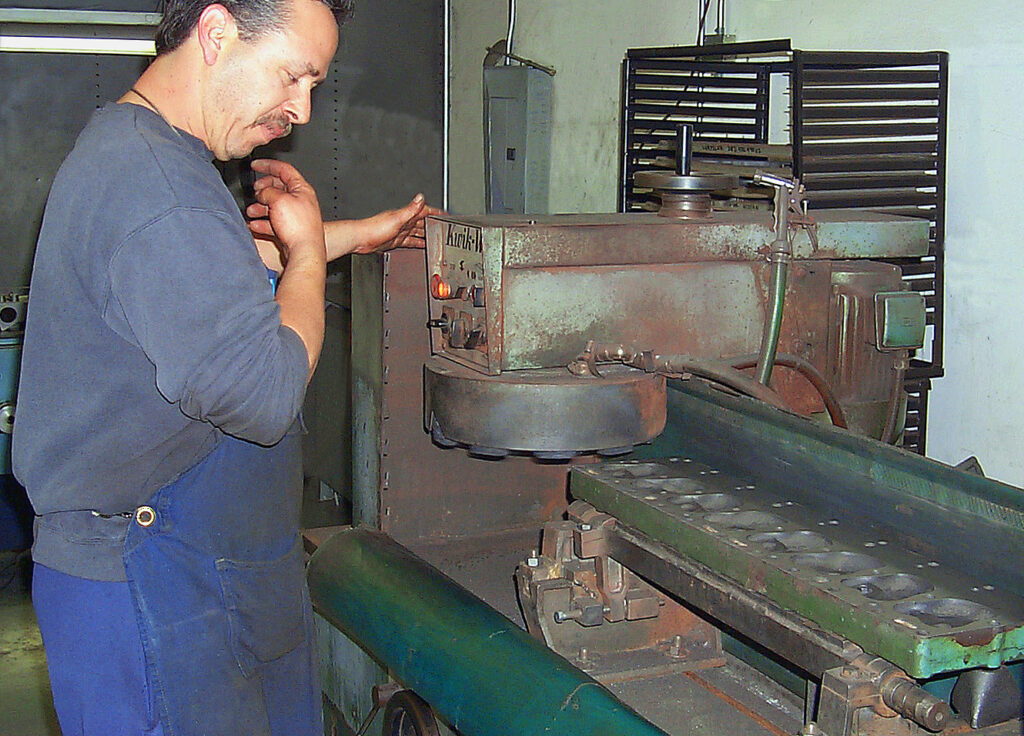

They did that because carefully assembling such components would produce the best possible engine, given the original configuration. It worked well, and you can do the same today. Start by finding a good machine shop. And even though you are building a stock engine for a classic, consider the specialty shops that build racing engines to machine your motor. Their services will cost more, but the speed freaks are used to working to exact tolerances.

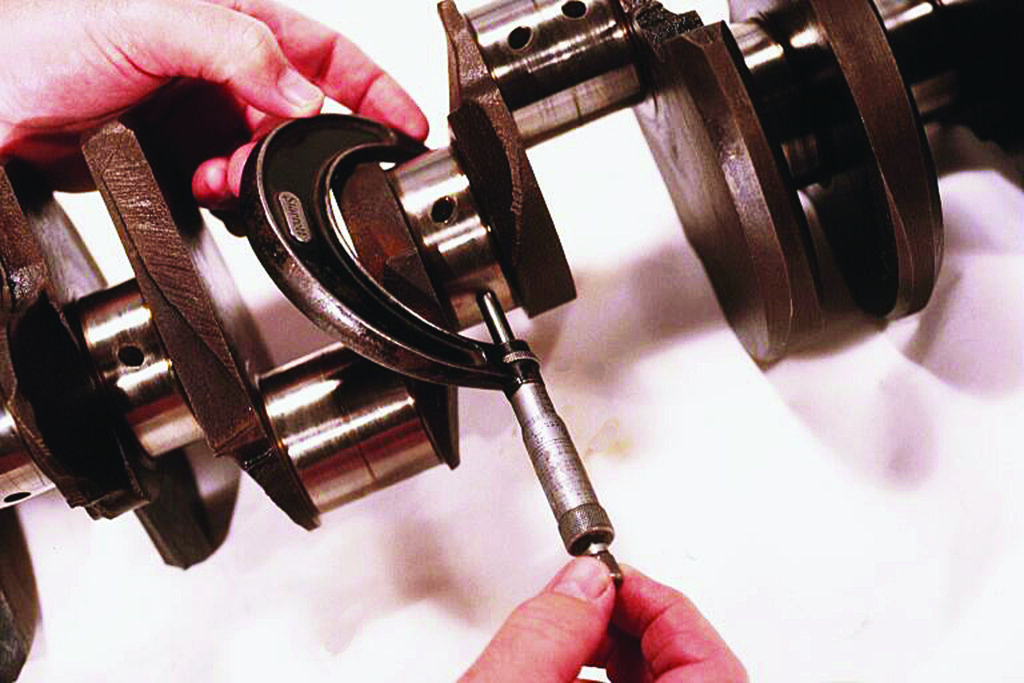

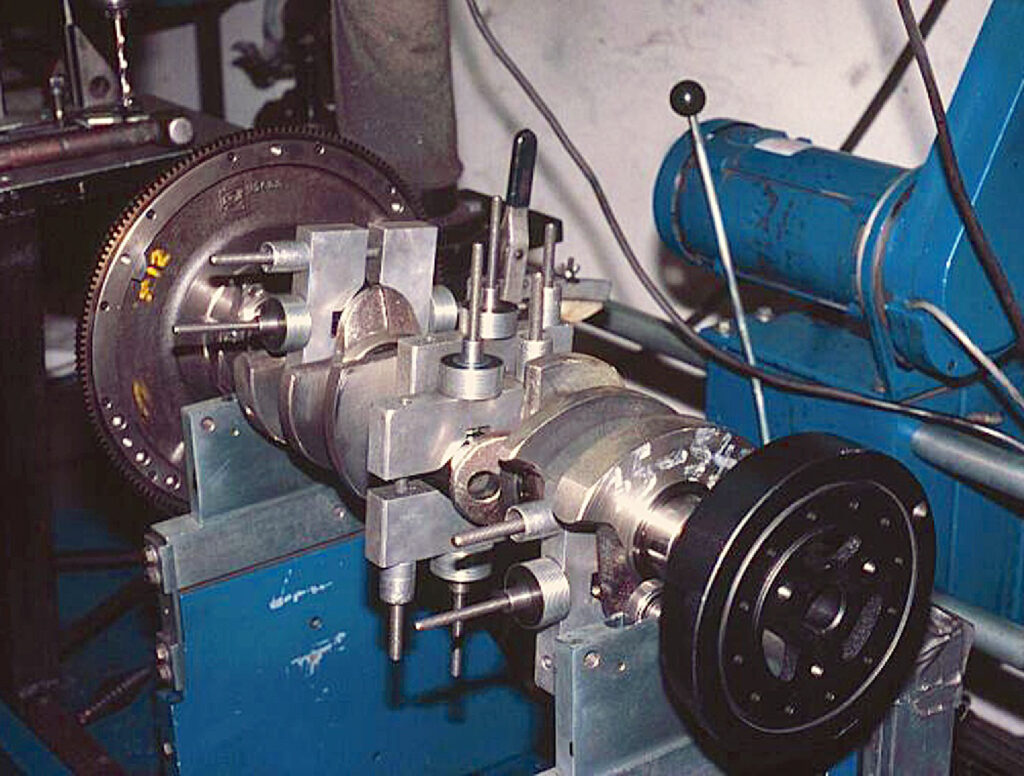

Also, any engine will benefit from having its rotating assembly balanced. When the pistons and connecting rods weigh exactly the same as one another, and the crankshaft counter-balance weights are drilled or filled to precisely offset the weight and mass of the pistons and connecting rods, the engine will run smoother, rev higher, and last longer.

Some good tricks

Don’t forget to take along the flywheel, clutch, and clutch plate, as well as the vibration damper, when you have your engine’s rotating assembly balanced. The flywheel and clutch should always be balanced, and in some cases, the vibration damper should be too. Once everything is properly balanced at the machine shop, you’ll be amazed at how smooth your old engine will idle, and how little — even at high rpm — it will vibrate.

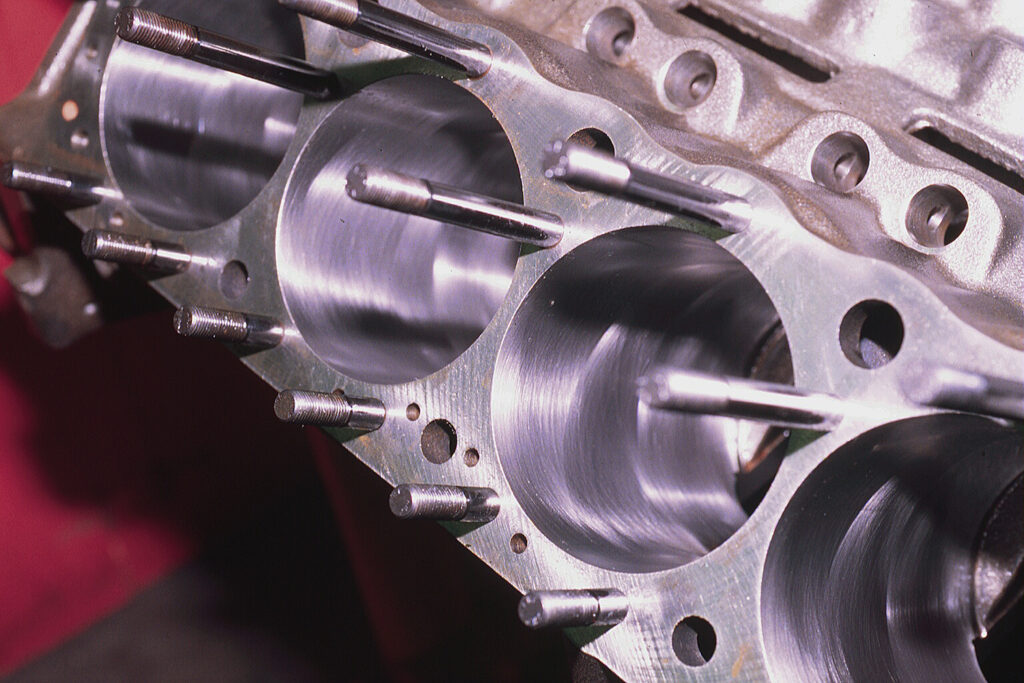

Another trick that can really make a power difference without doing anything to alter your engine’s appearance is to clean up its intake and exhaust ports. Just cleaning out the roughness and slag in the ports will make a big difference to your engine’s performance. It takes time, plus a high-speed grinder and some abrasive rolls to do it, but it is worth the trouble. The point isn’t to make the ports bigger as much as it is to clean them up to eliminate turbulence. If you want to see how this is done, Google YouTube and type in ‘porting heads for power’ by Jim Richardson.

In addition to removing slag and surface roughness, you can open the valve throats (also called pockets) and clean up and open the port runners to match the openings in the gaskets for additional power. Nothing you can do to most production engines will increase performance as much as pocket porting its heads. But I suggest you practice on a scrap head before you attempt it, or have a good machine shop do the job for you.

Valves

Another trick that can help your engine perform better is to do a valve job with a three-way cut.

Start with good-quality valves that can take unleaded, and if required, go to insert valve seats, and have your machinist do a three-way cut to seat the valves. This reduces drag right where it is the biggest problem, and enhances power. The cost is not much greater than a regular valve grind and is worth the trouble.

When assembling the connecting rods and mating the heads to the block, as well as the manifolds to the engine, use new bolts because your old ones may well have been stretched to their elastic limit. Also, when mounting heads to blocks, studs are a better way to go. Studs and nuts have a lot more clamping ability, and they can be torqued in place more evenly because when you tighten a nut on a stud, you aren’t twisting and clamping the stud and nut at the same time, the way you would with a bolt. ARP makes top-quality bolts and studs, and I recommend them highly.

Never use ordinary hardware store bolts when assembling an engine.