Of course, most of those cars are well and truly categorized as classics nowadays but nonetheless, many seem to have disappeared off the face of the earth. For example, when was the last time you spotted an early Zephyr, Holden, Valiant, Cortina, Vauxhall, Escort, or Triumph cruising down the motorway?

I suspect these classics are more likely to be seen on the streets of smaller, less-congested cities and towns throughout New Zealand, but in Auckland they’re a rare sight indeed. The other scenario that springs to mind is that there must undoubtedly be sheds around the country jam-packed full of these wonderful old classic cars — or at least I hope so, as they deserve to be preserved for future generations to admire.

All these thoughts flitted across my mind the second I saw Wayne Stockman’s beautifully restored New Zealand–new, Australian-assembled Ford Capri MkI. While my eyes swept the lines of this V6-powered beauty, I couldn’t remember when I had last seen one of them on the road. The sad thing is, I actually used to own one back in the late ’70s — unfortunately, one of the lesser V4 models. I begrudgingly purchased my Capri from my sister because she was having so many reliability issues with it. As it turned out, I was able to spend the time tinkering with the Ford and I eventually got it running properly.

The car you always promised yourself

It’s probably not at all surprising that Wayne developed an interest for Fords, as his earliest memories regarding family transport included Ford Cortinas and Falcons and, off theme, maybe the odd Holden or two.

Indeed, Wayne’s mother owned several Cortinas, as did one of his brothers, thus establishing something of a family tradition. So Wayne also decided to purchase a Cortina as his first car, and he ended up investing way more money into it than it was worth — something we’ve all been guilty of from time to time, I’m sure.

However, Wayne’s first involvement with Ford’s Capri took place about 14 years ago when he was searching for a restoration project and hobby. He’d always had an interest in classic cars — particularly American muscle cars from the late ’60s and early ’70s as long as they wore the blue oval — but decided a Capri would be more suited to his budget at the time.

Although Wayne was naturally biased towards owning a Ford, he did consider several other options, including a Honda S800 and even a Sunbeam Tiger, but he felt more comfortable around Fords.

Wayne recalls when his father started restoring cars during the early ’80s he was no mechanic or panel beater by any stretch of the imagination, but the can-do, give-it-a-go attitude he learned growing up on a farm during the ’40s and ’50s — where you fixed everything you had or went without — put him in good stead for projects such as the Ford Cortina GTE featured in a previous issue of this magazine (New Zealand Classic Car, April 2008), as well as several award-winning vintage car and motorcycle restorations. It would seem that Wayne inherited much of his father’s attitude, and he was determined to try and accomplish as much restoration work as possible.

Wayne initially looked at the possibility of purchasing another Cortina or an Escort, but couldn’t really find anything he liked. Then he recalled that back in 1983, when he started his first job, one of his colleagues owned a pre-facelift MkI Capri 3000E. It had been painted bright purple, had been fairly well modified by its current owner and went as fast as it looked. Wayne reckons it was definitely the car to be seen in, especially on a Friday night. The memories of that car — firmly entrenched in his subconscious — came back when he spotted a Capri up for sale. Wayne discussed at length with his father as to whether this 3.0-litre Capri would be a suitable restoration project. The parental advice was that he should look for a 1600GT, as Wayne’s budget at the time didn’t really stretch to a V6 performance car.

Despite his father’s recommendation, Wayne decided to investigate the advertised car further, discovering that the Capri’s owner was a school teacher in Brookby and her husband was an aircraft engineer. Wayne also learned that some restoration work had already been started on the Capri, despite the fact the couple’s daughter was still driving the car regularly. As well, although the Ford was fitted with an incorrect bonnet, the original was being offered with it. The owners were relocating back to the UK and, following much thought, Wayne decided to proceed with the purchase, taking ownership of the car on the day the previous owners flew out of the country.

The Capri caper

So, in 1999 Wayne finally had his restoration project, a 1971 Australian-assembled Ford Capri 3000GT. The car ended up sitting in storage for a couple of years due to an addition to the family, and the purchase of a new home.

Once Wayne was able to get reorganised, he moved the Capri to his home garage and began restoration work. The general overall condition of the Capri wasn’t the best. Its paint was long past its prime with many touch-ups visible, a number of which were delaminating. >

As well, the decals were completely missing on one side of the car. The V6 had a terrible miss, one brake caliper was completely seized and all the dash wiring was hanging out from under the dash.

It came as quite a relief when Wayne discovered the Capri had virtually no rust in the body — something he ascertained after stripping the paint and filler off the car using everything from paint stripper to scrapers, poly pads and anything else he could lay his hands on. At this stage the car was stripped to a bare shell in Wayne’s garage — not a single screw was left untouched. As space was limited, he made up a couple of dollies mounted on wheelbarrow wheels at the back and swivel wheels up front, so he could manoeuvre the body around. Wayne remembers stripping the last millimetre of paint off the body the night before his first son was born.

He also discovered that the factory underseal was intact and still in excellent condition (apparently English-assembled Capris were not undersealed) and decided just to clean it, check for any loose pieces and reseal. The sills were stripped to bare metal and revealed no rust, but a huge amount of filler disguising dents. These he pulled out with the aid of a nail gun, and a good mate had them straightened before a minor rust area in the bottom of the driver’s side guard was cut out and a new piece fabricated by Wayne and welded into place. He hadn’t wire welded since his high-school days so a spot of practice on some old steel with a borrowed plumber’s welding set was needed before he applied heat to the Capri’s important parts.

The refurbished bodyshell was transported to a local paint shop and prepared for painting. Wayne chose a two-pack system, primarily because of its durability and the finish being easier to work with, although he admits that the primer was so hard it took him eight weekends of solid sanding just to get it ready for final painting. Once painted in the original Vintage Burgundy colour, the body was returned to Wayne’s garage in preparation for the large reassembly job that lay ahead.

Whilst the body was in the paint shop Wayne stripped and repainted many items — such as the cross member, front struts, steering rack and many other suspension components ready for installation. The front suspension also received new bushes and inserts, new track control arms, NOS strut tops, brand-new springs and the rear springs were re-tempered and re-set by Snell Springs and had NOS bushes fitted. New shock absorbers were fitted and the rear brake drums were re-skimmed with new shoes and wheel cylinders were fitted onto refurbished backing plates. The differential was completely stripped, repainted and reassembled, only requiring new wheel bearings as all the internal components were in perfect condition. The front disc brakes were replaced with brand-new rotors and the calipers were stripped and reconditioned with new seals and re-fitted. New front wheel bearings were also installed.

Precautionary measures

Thought it had only completed just over 105,000km (63,000 miles), Wayne decided to strip the Capri’s V6 engine completely and have Paramount Engineering rebuild it. He managed to source two brand-new cylinder heads, camshaft, pistons, rings, water pump, oil pump, bearings and gaskets, all NOS parts, and once the basic rebuild was complete he took everything home for painting.

Then it was time to install the exterior items onto the engine such as the fan, new alternator, NOS exhaust manifolds, and the fully restored carburettor, distributor and completely rebuilt radiator. > Wayne was able to repaint most of the smaller ancillary items, such as the original air cleaner and fittings, again stripping them to bare metal, and repairing them before painting.

The gearbox was disassembled and inspected by Steward Motors in Howick. Luckily, Wayne lives only metres from the workshop and was able to deliver the box on a hand trolley. As it turned out, the gearbox was in very good condition internally although, as a precautionary measure, new bearings were fitted before final reassembly.

Due to the lack of working space in Wayne’s garage, he wasn’t able to assemble the engine and gearbox onto the cross member before lowering the body onto it — as it was originally accomplished by the factory. Instead, he had to assemble the engine and gearbox, and then lower it into the engine bay on an angle, which doesn’t allow for any tolerance and can have disastrous results on newly painted panels if not done carefully and precisely, which he was able to do with the help of his father. The driveshaft received new universal joints, balanced and repainted before being fitted.

The next step was to install the interior. The original headliner was refitted and a new white seat upholstery kit was imported from Australia and fitted to completely refurbished seat frames. The original door panels were beyond repair, so Wayne also imported a new pair of reproduction panels from Australia, whilst the original rear quarter cards were kept. New reproduction carpets from John Roberts in Melbourne were fitted.

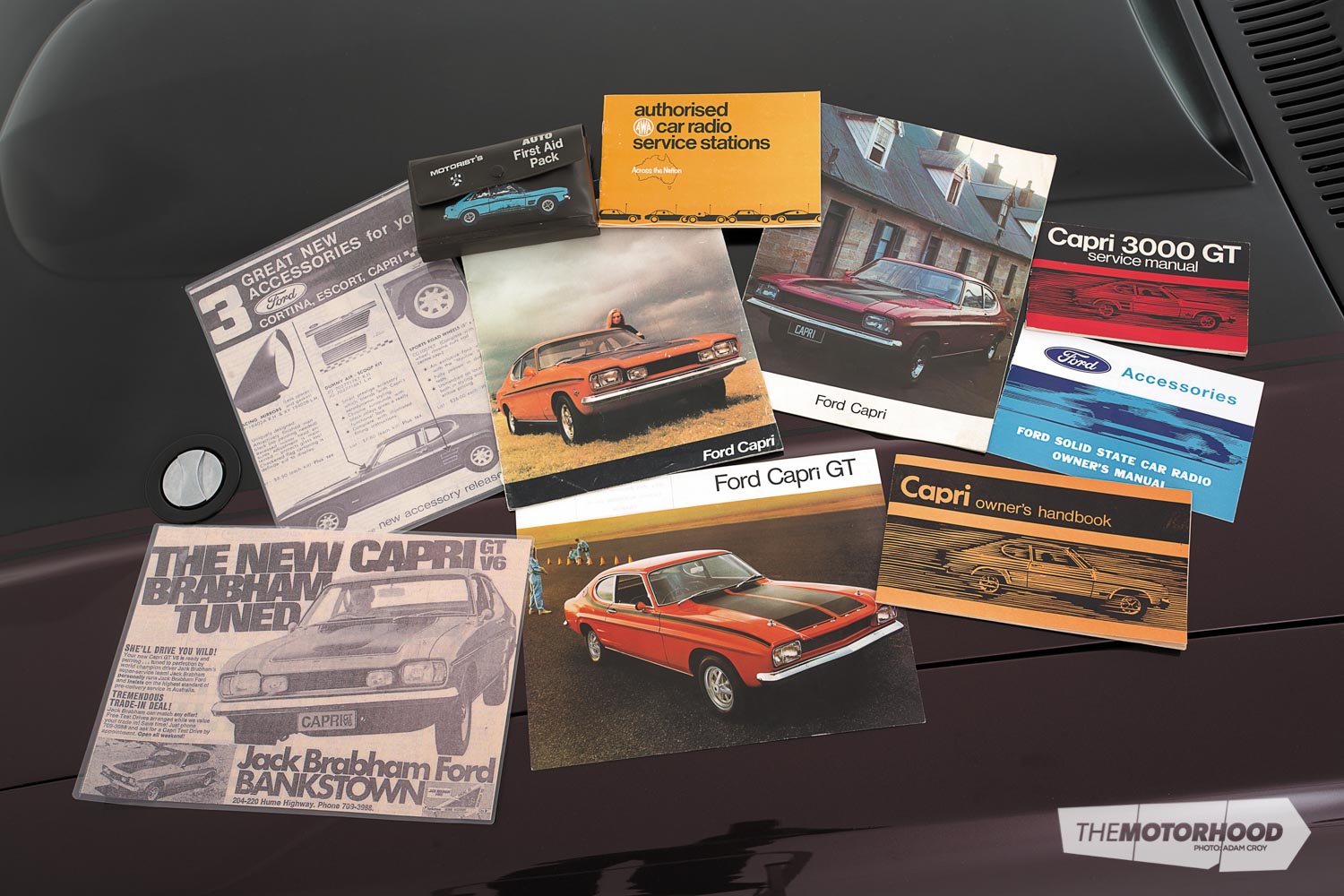

The dash was removed and refurbished whilst NOS switches and air vents, original factory radio and gauges were refitted along with the centre console once Wayne had reproduced the wood-grain inserts.

As an aside, Wayne managed to source the NOS parts from all over the world including such places as Singapore, Australia, Malaysia, Thailand, Malta, Greece, Israel, Italy, Poland, the US — the list goes on — apparently possible due to the fact the Ford Capri was sold and distributed to more countries than any other Ford at the time, such was its success. However, unlike the car that originally inspired the Capri, the Ford Mustang, you cannot simply order brand-new reproduction parts from a catalogue, so parts for the British coupé are not cheap.

New Zealand also proved to be a good hunting ground for parts, and Wayne remembers wandering around a swap meet in Pukekohe and spotting a unique Capri 3000GT gear knob sitting on a tarpaulin amongst a pile of other parts. When he asked the owner for the price, the answer was $40. Wayne’s reply was, “If I can tell you what car it belongs to, can I have it for five dollars?” No doubt with a smile, the swap-meet stand owner agreed and then received a bit of a surprise when Wayne gave him chapter and verse on the origins of the gear knob. Needless to say, Wayne paid only five bucks for the item and, as an aside, the two men have kept in touch ever since.

Australian connection

All the glass in the Capri remains original except for the windscreen, which was so badly scratched and pitted it had to be replaced. According to Wayne it was like looking through a pair of badly scratched sunglasses. Luckily, he was able to source the original style, Ford Safety Standard laminated glass with the tinted option.

Wayne chose to repair and have the front bumper re-chromed because of the two mounting holes positioned on the underside. Apparently these holes were used to mount lower fog lights in countries such a Sweden, where fog lights were prohibited from being mounted to the topside of the bumper. The original rear bumper was also re-chromed and the anodised aluminium side trim was straightened and reconditioned. The taillight and headlight trims are brand-new items, as are the headlight, taillight and indicator lenses. The stainless steel trim along the sills was polished, another task Wayne had to learn before handling the task himself.

The exterior striping kit was sourced from Australia and is a replica of the original kit, whilst the ‘SUPER ROO’ decals on the front guards are genuine items, courtesy of an XW GT Falcon, as are the bonnet twist locks. The exterior mirrors were donated by a XY GT Falcon. The badges on the car, unique to Australian-assembled vehicles, were badly faded and damaged, so Wayne stripped them apart and had the centres reproduced.

The wheels on this car are a factory option, as was the steering wheel. According to Wayne, the factory options available on Australian-assembled Ford Capris were numerous, and most were dealer-installed items.

Parts such as the familiar dummy side vents were not fitted as standard in Australia, nor were bumper over-riders.

The wheels on this car are called Contessa, originally made by ROH in Australia at the time. They also made 12-slot and Bathurst Globe wheels for GT Falcons, Cortinas and Escorts. Contessa wheels consist of a steel rim with a pressed-in aluminium centre. Wayne managed to source these wheels from Australia.

In fact, he made a complete set from eight wheels, and the centre caps and nuts are reproductions specially made here in New Zealand.

Wayne also began to carry out some research into these cars and discovered they were indeed quite unique compared to their English-assembled cousins. There are many subtle differences, such as the chrome along the sills. The exterior mirrors and interior are unique to the Australian-built Ford Capris. In fact, many items were sourced from the XW/XY Falcon, as a percentage of local content was required in the building of these cars at the time. This one’s paint and interior combination is also very unique, even in Australia.

Wayne commenced his restoration project in 2001 and finished in April 2008. Since then, he has attended every Capri Car Club AGM and has achieved many awards with his Capri — including Best Interior, Best Paint, Best MkI (now five years running) and People’s Choice, an award Wayne admits to being quite chuffed about as this was, of course, judged by the public.

During the restoration, Wayne has tried to achieve as much as he could himself. As he says, “That’s what this hobby is all about!”

We couldn’t have said it better ourselves.