The pursuit of speed is something that Reg Cook has spent the majority of his adult life chasing, be it on the race circuit, on gravel, or, more recently, on the salt, adding land-speed records to his résumé. But it’s perhaps his latest project, a land-speed streamliner, that is his most ambitious to date. A little over three years in the making, from an idea conceived in the lunch room at CMR, it’s been a collaborative effort between around 30 Kiwis to turn the project into reality.

When we showed up at CMR, deep in the South Auckland countryside, a team of four guys were thrashing to get the finishing touches completed. The car was only days away from being loaded into a container destined for California. Once there, it will be towed to the hot rod holy grounds that is the Bonneville Salt Flats in Utah for Speed Week. The fact that the event happens only once a year — for only one week, and is halfway around the world — means Reg and the team not wasting any chances to pen CMR into the record books as many times as possible.

There is a well-mapped-out development plan for the car, with the ultimate goal of running over 500kph — speed the guys won’t see for a few years. Reg tells us that just getting through scrutineering for the first time is a major hurdle, with 80 per cent of streamliners failing the first time around. Once that is out of the way, the car will have to run a succession of passes to prove it’s safe — not only for the safety team, but for CMR themselves.

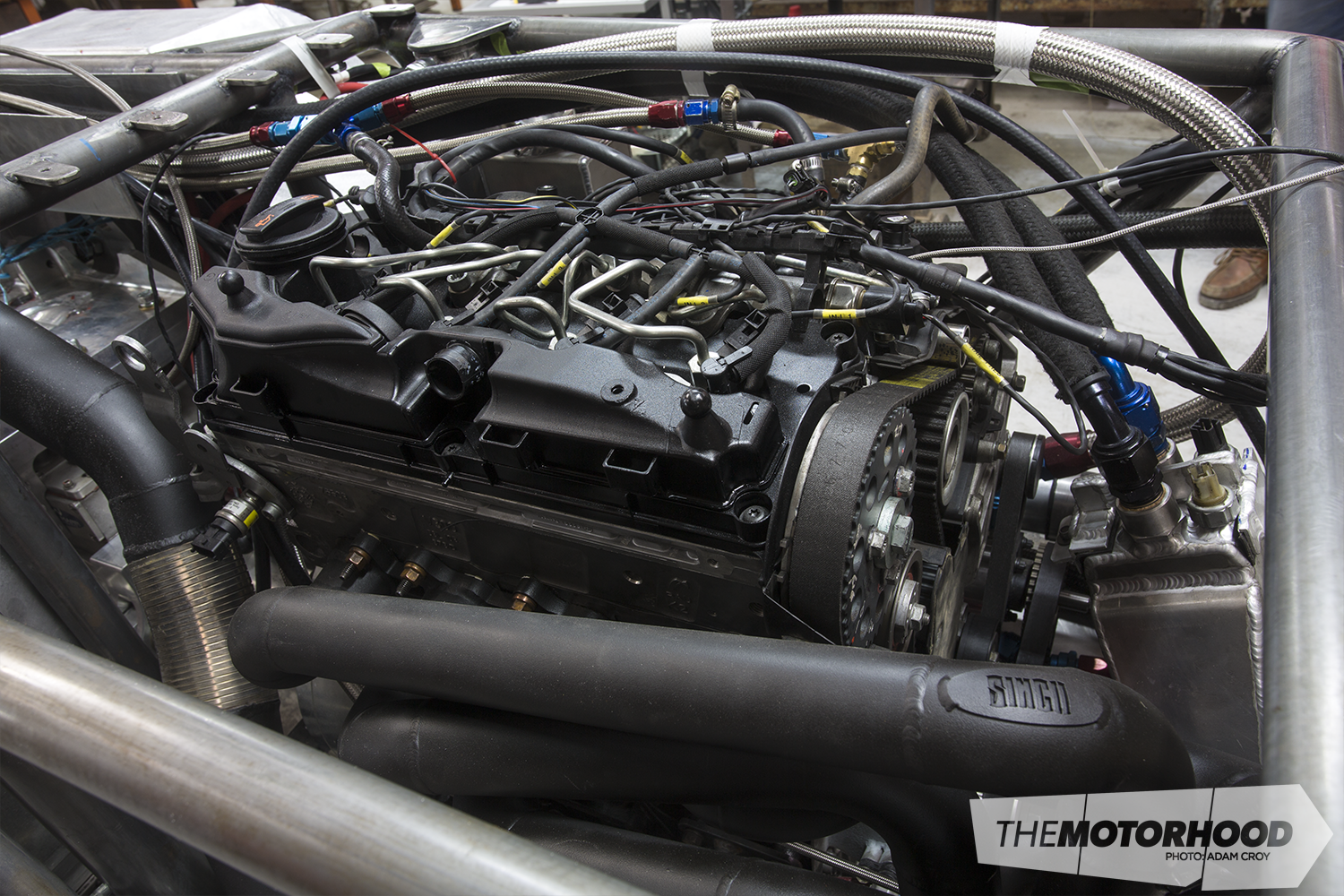

So, for the first Speed Week, the guys have set their sights on running 220mph (352kph), which is likely the fastest speed they will be allowed to achieve. The team hopes the engine — a modified two-litre turbo-diesel from a VW Amarok — will be sufficient to propel Reg to this speed. The engine is said to be putting out around 30 per cent more power than stock, although Reg is keeping his cards to his chest as far as actual numbers go. What we can tell you is that it’s received a Garrett turbo, sitting on an intricate Sinco manifold with dual Turbosmart wastegates.

The team will take three of these engines over with them — one standard, and two modified versions — that Reg developed on the CMR in-house engine dyno. The record that the team are chasing is 147.90mph, but they are planning to exceed this by nearly 100mph.

Fitting everything inside the tight confines of the framework, which measures only 940mm across, has made for some interesting workarounds. This large icebox serves as a cooler for the engine, the intercooler, and feeds water jets that are mounted underneath the body to stop salt build-up — a real concern when your ride height is only 63mm. An air feed for the driver also runs though the bottom of the tank, as there was nowhere else to fit it. The cooler air is a welcome bonus for Reg.

Packed around the icebox are the fuel, coolant, oil, and hydraulic systems. Only a single Bosch 044 fuel pump is needed to fuel the engine. No exotic race fuels here — this diesel will be one economical speed machine. The hydraulic system powers the jacking system — air jacks simply would not cut it due to the weight of the streamliner and the height that the team wanted to lift it to.

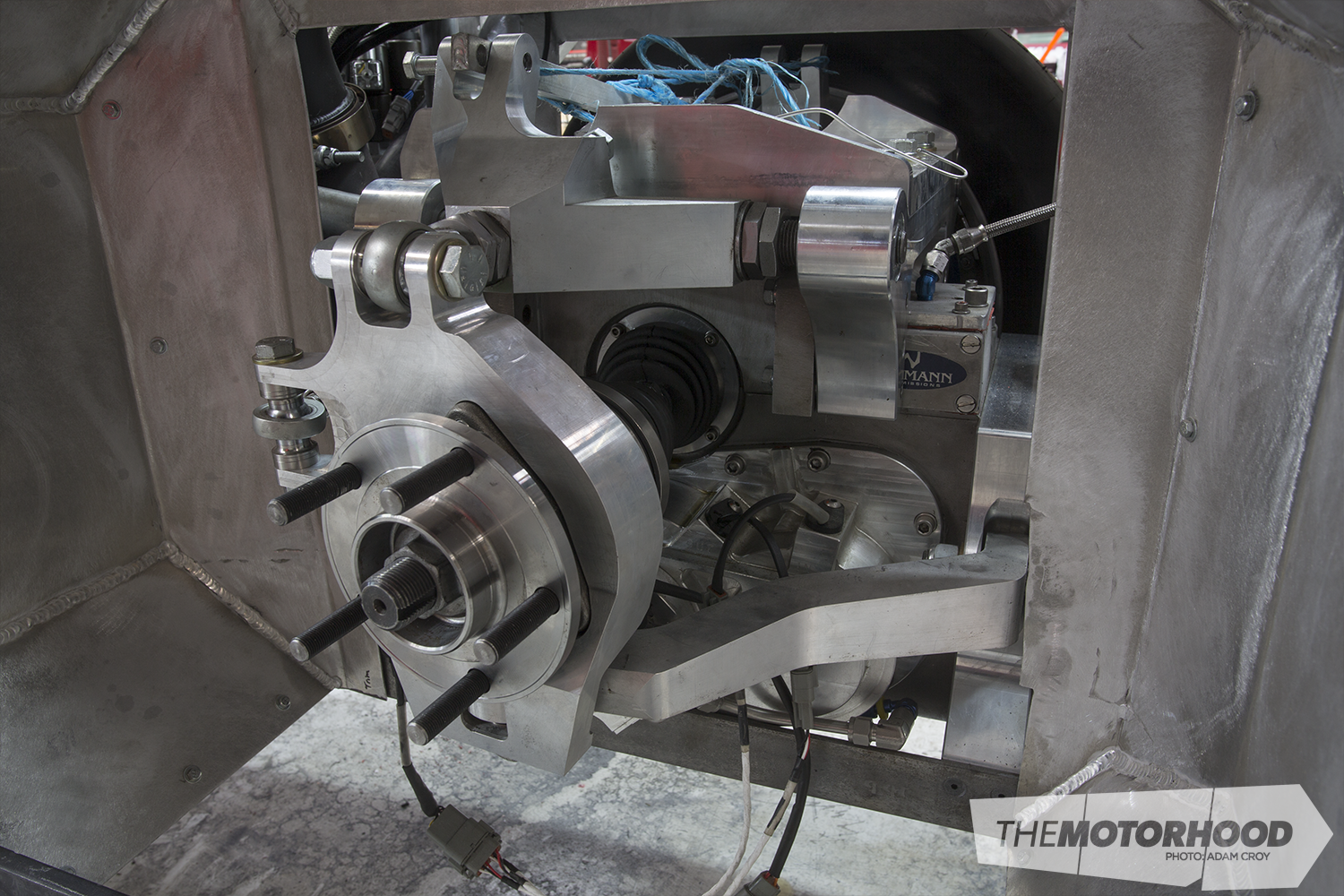

The project features some great billet components built and machined by Richard Mason, the bell housing that connects to the eight-speed Wiseman gearbox being one. The theory behind front-wheel drive is that it allows the streamliner to have all the width up front, and taper off to a narrow end. On paper, the team think it will give high-speed stability, but there is only one real way to find out.

During the first event, Reg will only get as far as fourth gear to reach the goal of 220mph. Yep, this eight-speed might be overkill for this attempt, but it’s future-proofing the car for the 300mph runs in a few years. First gear is extremely tall, and the car needs to be pushed off the line to around 80kph before Reg can pull away under his own power. The front suspension is all billet, and runs inboard Koni adjustable shocks with a 1500Ib spring rate.

And how about the turning radius? Try 400 metres! Yep, as per the rule book, at least two of the four wheels must be covered, and all four billet wheels are enclosed as per the team’s design. The fronts are housed in these wheel tubs, designed to reduce the amount of salt entering the engine compartment — a real issue for anyone racing on the salt surface.

When running at these speeds, there is only one brand of tyre available on the planet. Rated to 300mph, these Bonneville-specific treads are designed not for grip, but to handle the high-speed centrifugal forces that the wheel experiences at these speeds. The salt itself is a funny surface — it’s extremely hard in an impact force, but not in terms of abrasion. Many lightweight machines use drag car front runners as tyres.

The driver’s compartment is a cramped place, with a cage only just big enough to house Reg and his helmet. It takes 15 minutes to strap him in there, and he must be able to get himself out within 15 seconds — a feat that is only made harder by his age of 70. To help the situation, the dash cluster features a very cool quick-release mechanism, allowing it to swing out of the way with one click.

We had the pleasure of watching as Reg sat down in the seat and closed the lid for the first time, and we imagine it’s going to be a lonely place at over 200mph in the middle of a white salt abyss. The noises generated at that speed must be incredible. The hatch itself was built in-house, and swings forward on a large alloy piano hinge.

As per the rules for a streamliner, it must have four wheels, but the configuration is left open. The team has developed two inline rear wheels that are sprung on dual trailing arms. The front wheel was not in at the time, but looks identical. Having the wheels in line allows the frame to narrow considerably.

The trailing-arm design is copied from a motorcycle, and features a single Koni coilover with billet mount and a 1000lb spring rate. While the streamliner will have minimal travel, it does need suspension, although how all this stuff is going to work is somewhat of an unknown. The team have huge 50kg lead weights that bolt to the frame, and they’ll will be used to tune the weight balance if needed. It’s been an odd project for the team — unlike a conventional race car build in which weight is a huge factor, it was not a priority with this project, which weighs in at just under 2000kg.

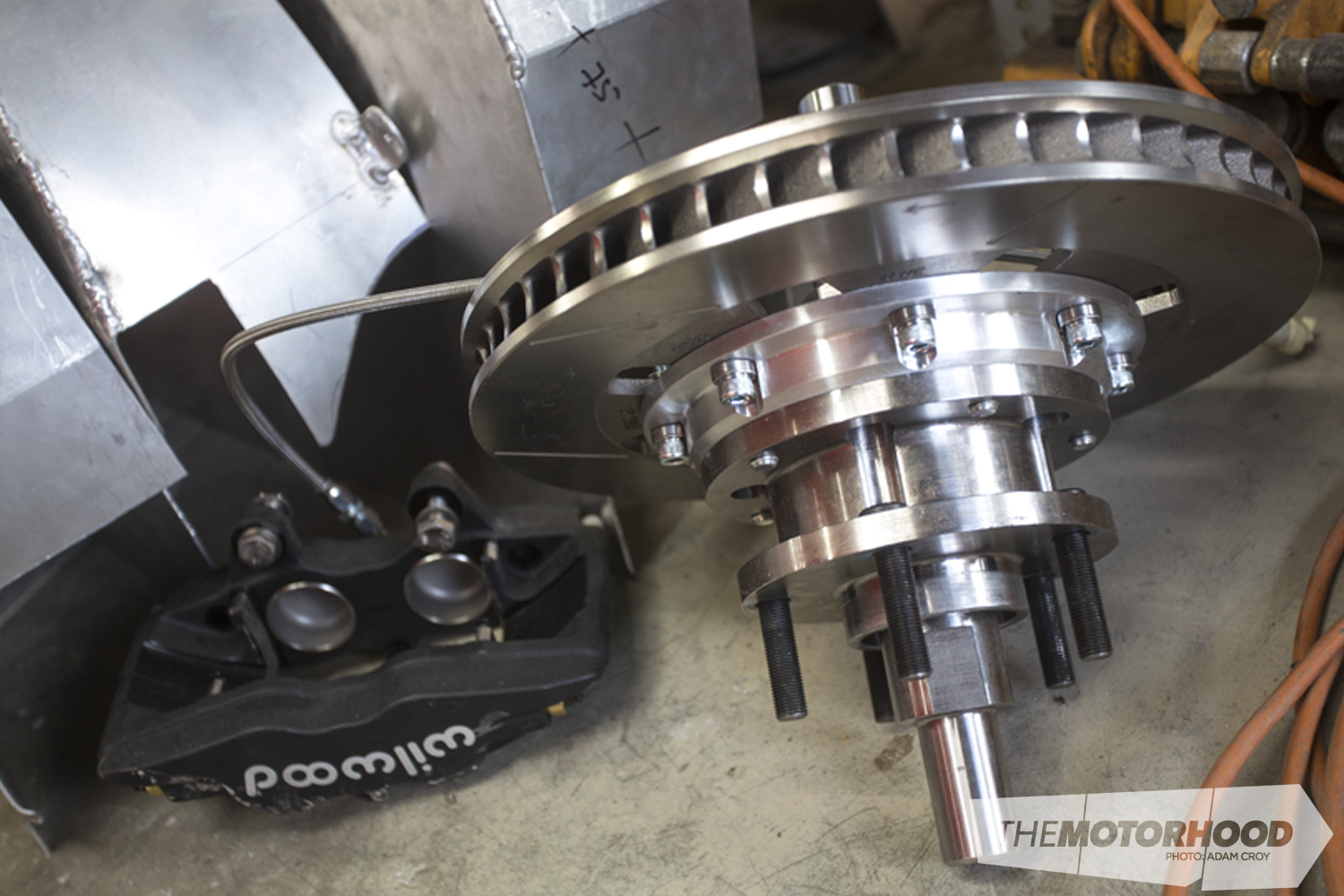

Both rear wheels have large Wilwood brakes fitted — although, like any car that moves at these speeds, it will be parachutes that do all the work. The pair of chutes are mounted on the rear of the bodywork.

The bodywork is all fibre-reinforced plastic (FRP) and bolts on in stages. At just over nine metres long, it’s been a massive job in itself. The goal here was not to create downforce, but as little drag as possible. The team will spend a great deal of time CFD modelling this and tweaking the shape ahead of a much lighter carbon-fibre version for next year.

While it might look like that hole is for the exhaust, it’s actually where the parachutes mount. The small bar poking out of the tail is for the 80kph push-starts, and the small perspex window will house a greenstone Taniwha. To say Reg is a proud Kiwi would be an understatement.

The trailer that the team are taking with them is designed to fill a 40-foot container, and features airbag suspension to maximize the amount of available space. Those three black bars across the top will be touching each side of the container. Inside, the trailer will be carrying both the streamliner and the NX Coupe, a world-record holder in its own right. Reg is taking it back with a naturally aspirated and nitrous-fed Honda K20 engine, in the hopes of a few more records — talk about maximizing the trip!